TM 5-3740-214-14

Table 5-3. Direct and General Support Maintenance Troubleshooting (Continued)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

ENGINE DOES NOT TURN OVER (Continued)

(1)

After removing the armature from the starter, place the end caps back on the shaft. Check the

shaft and bushing fitting.

(2)

If the shaft is loose in the bushing, replace the bushing and go to Step 3g.

(3)

If the end of the shaft is worn, replace the armature.

(4)

If the armature shaft fits the bushing correctly, check the commutator.

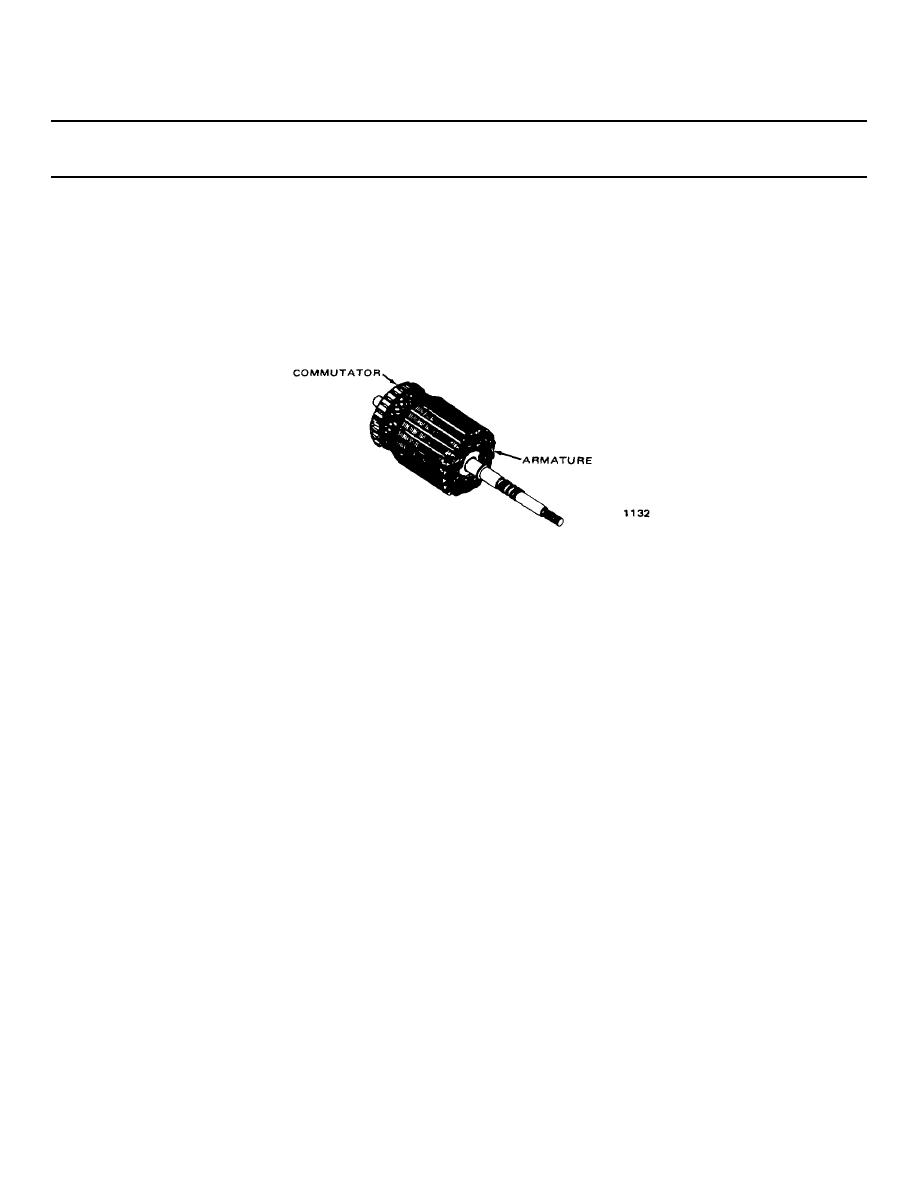

Figure 5-58. Armature

g.

Check the commutator.

CAUTION

DO NOT use emery cloth to clean the commutator.

(1)

Clean the commutator. Use number 00 sandpaper.

(2)

If the commutator has any of the following signs, replace the entire armature and go to Step 3h.

Wearing

Pitting

Burned

Out of round

Has high insulation between the bars

(3)

If the commutator is ok, go to Step 3h.

h.

Check the armature for opens.

(1)

Check for loose leads between the armature conductors and the commutator bars.

(2)

Resolder any loose leads and go to Step 3c. Use rosin core solder.

5-53