TM 5-3740-214-14

Table 4-3. Troubleshooting Chart (Continued)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

NOZZLE PRESSURE GREATER THAN 100 PSI (Continued)

NOTE

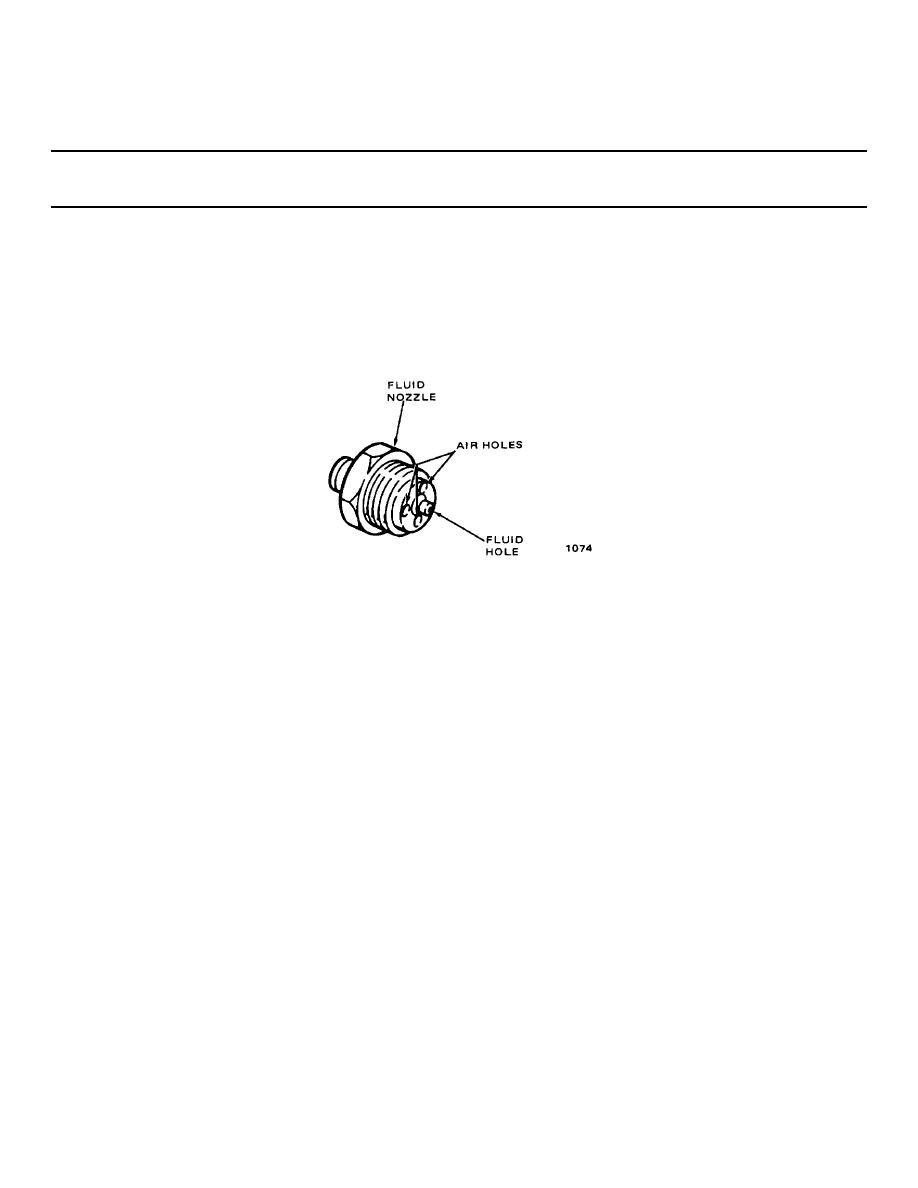

Be sure to check the air groove in the back of the fluid nozzle and clean it as necessary.

(4)

If air cap is not plugged, or coated with oil residue; go to Step 1b.

Figure 4-75. Fluid Nozzle

b. Remove fluid nozzle and check air holes.

(1)

If air holes are plugged, soak the fluid nozzle in acetone (O-A-51F) to dissolve the

gunk and varnish.

(2)

Carefully clean out the fluid nozzle holes with a toothpick or other soft non-metallic

object.

(3)

Wipe the fluid nozzle surfaces with a clean rag. Go to Step 1c.

(4)

If air holes are not plugged, go to Step 1c.

CAUTION

DO NOT use tools to tighten the knurled ring. Tighten it by hand. Too much force will damage

the nozzle assembly.

DO NOT use too much force to tighten the fluid nozzle. Too much force will damage the tefIon

gasket.

c.

Reassemble nozzle assembly and start engine. Check the pressure gage.

4-67