TM 5-3740-214-14

Table 4-3. Troubleshooting Chart (Continued)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

NOZZLE PRESSURE BELOW 90 PSI (Continued)

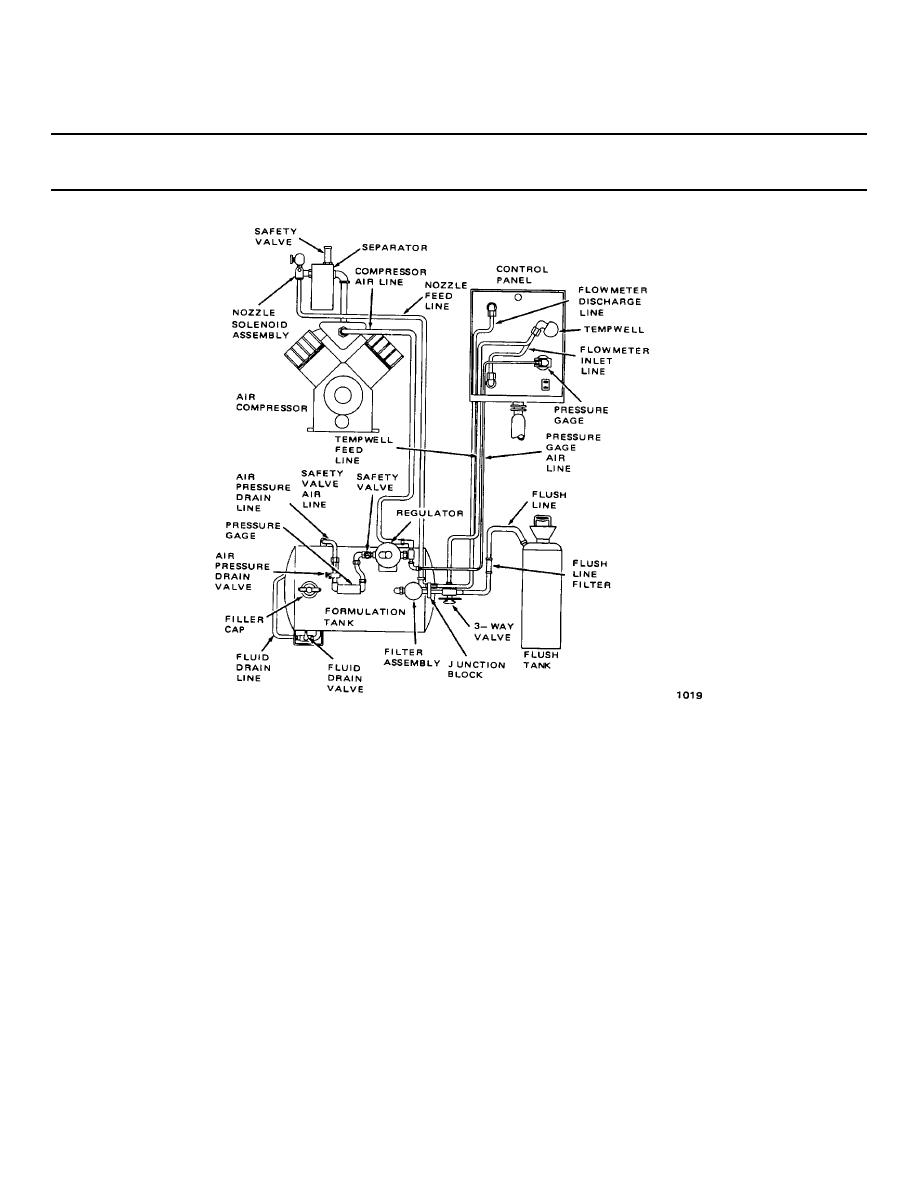

Figure 4-69. Hoses, Lines and Fittings

Step 5.

Check pipe fittings listed below for air leaks.

Pipe elbow and nipple between pulsation tank and separator.

Street elbow at separator.

Pulsation tank pipe plug.

a. If above fittings are loose, tighten them when they reach their normal operating temperature and

go to Step 5c. Be careful not to be burned.

b. If fittings above are warped and cannot be tightened to stop air leaks, replace them and go to Step

5c.

c.

After tightening or replacing any of the above parts, start the engine and check the pressure gage.

(1)

If pressure is 90-100 psi, the problem is solved.

4-62