TM 5-3740-214-14

Table 4-3. Troubleshooting Chart (Continued)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

NOZZLE PRESSURE BELOW 90 PSI (Continued)

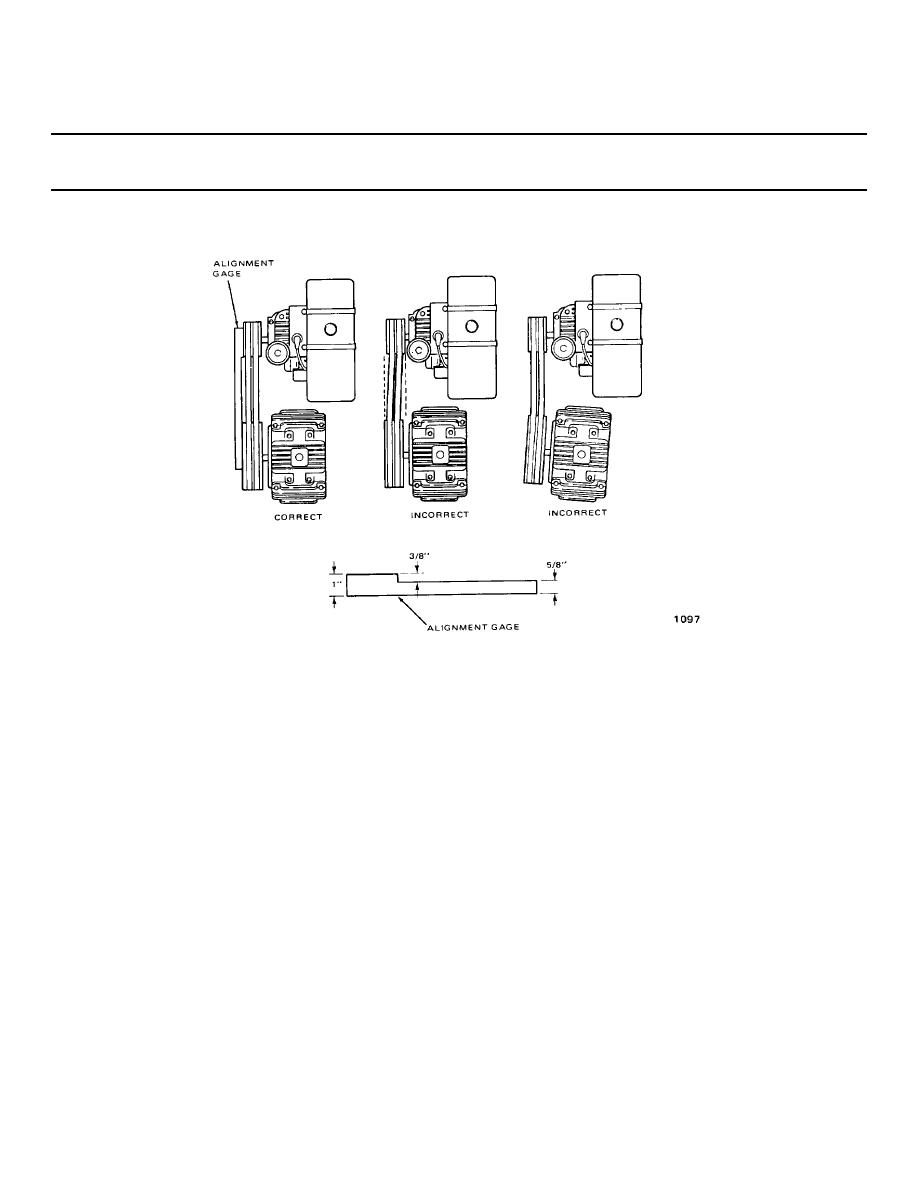

Figure 4-72. Compressor Alignment

NOTE

An alignment gage can be made from a piece of scrap metal or wood and can be used to line up

the pulleys.

c.

Adjust the belt tension.

(1)

Loosen compressor mounting nuts. Do not remove them.

(2)

Line up the pulleys.

(3)

Turn tensioner screw to the right (clockwise) to tighten the belt tension.

(4)

Tighten compressor mounting screws.

(5)

Install belt guard.

d. Start the engine and check the nozzle pressure.

(1)

If pressure is between 90 and 100 psi, the problem is solved.

(2)

If pressure is less than 90 psi, notify your supervisor of the problem.

4-65