TM 5-3740-214-14

Table 4-3. Troubleshooting Chart (Continued)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

NOZZLE PRESSURE GREATER THAN 100 PSI (Continued)

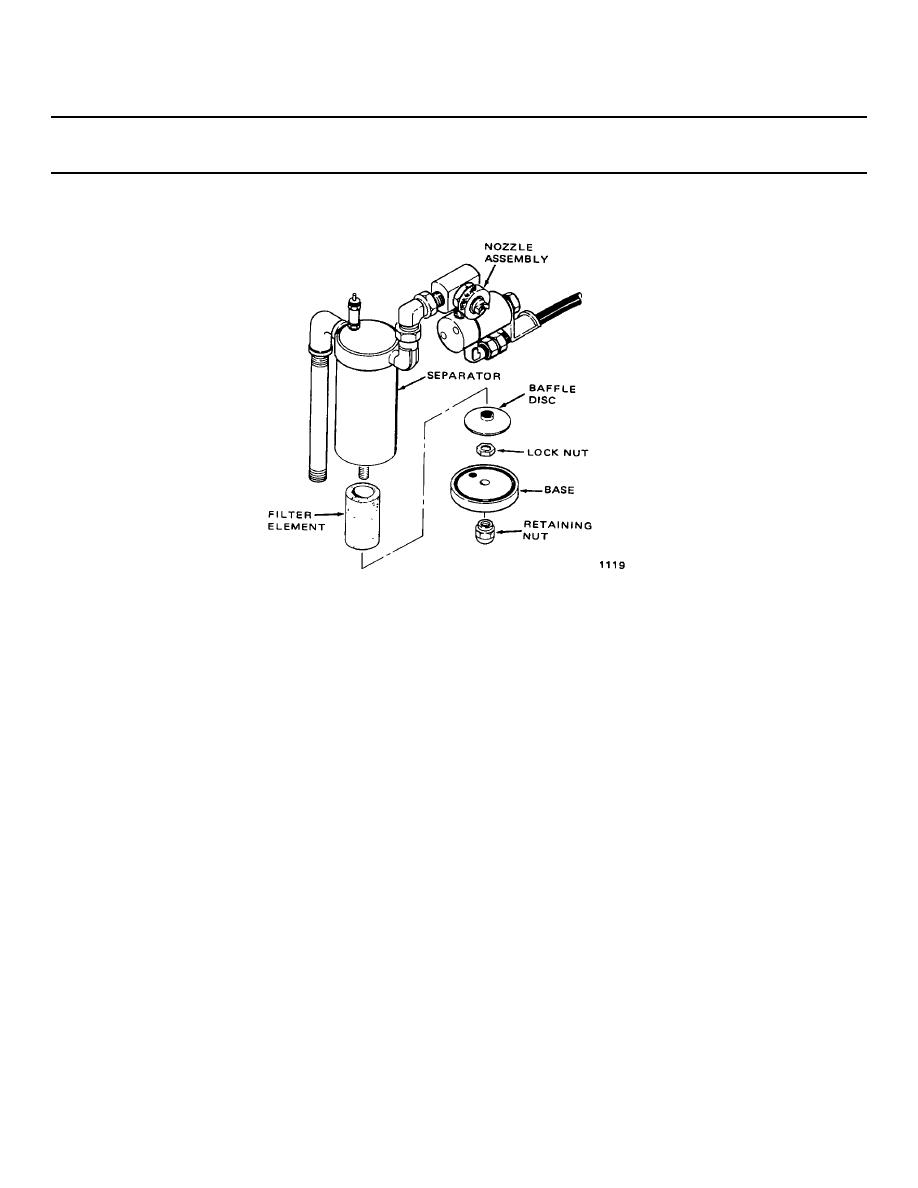

Figure 4-76. Separator Assembly

(1)

If pressure is 90-100 psi, the problem is solved.

(2)

If pressure is still greater than 100 psi, go to Step 2.

Step 2.

Check separator filter element.

a. Disassemble separator.

(1)

Remove bottom retaining nut.

(2)

Remove separator body and bottom.

(3)

Remove filter lock nut, baffle disc and filter element. Go to Step 2b.

b. Inspect filter element.

(1)

If filter element is plugged, replace it and go to Step 2c.

(2)

If filter element is ok, go to Step 2c.

c.

Inspect bottom gasket. If gaskets are cracked or broken, replace them and go to Step 2d.

d. Reassemble separator and start engine. Check pressure gage.

(1)

If pressure is 90-100 psi, the problem is solved.

4-68