2-40

TM 3-4230-209-30&P

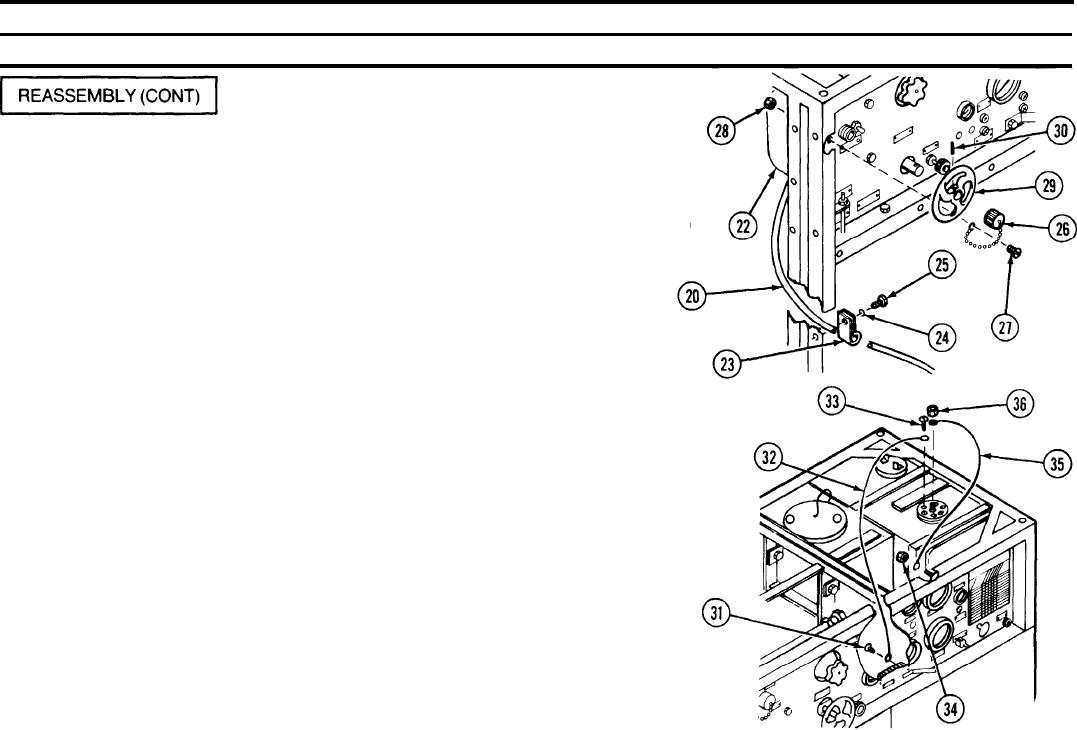

2-14. PUMP UNIT ASSEMBLY (CONT).

LOCATION/lTEM

ACTION

REMARKS

Loop clamp (23)

Slide loop clamp (23) around cable (20) and secure with flat washer (24)

Flat washer (24)

and hexagon head cap screw (25).

Hexagon head cap

screw (25)

Electrical connector

Screw electrical connector cover (26) onto HEATER RECEPTACLE AND

cover (26)

SWITCH socket on the alternator junction box (22). Secure the end of

Machine screw (27)

chain with machine screw (27) and hexagon head self-locking nut (28).

Hexagon head self-locking

nut (28)

NOTE

Handwheel may be held on with a drive pin.

Handwheel(29)

Slide handwheel (29) onto VALVE NO. 1 MANIFOLD stem and tighten

setscrew (30).

Setscrew (30)

Remove screw (31) from TB1-G and install wire (32). Remove machine

Screw (31)

Wire (32)

screw (33) with lock washer from fuel quantity transmitter flange. Insert

Machine screw (33)

machine screw (33) through terminal on end of wire (32) and reinstall

machine screw (33) with lock washer and tighten.

Nut (34)

Remove nut (34) from top screw securing the VACUUM GAGE. Attach

terminal lug on end of wire (35) to end of top screw and reattach nut (34).

Wire (35)

Remove nut (36) from center stud on fuel quantity transmitter and attach

Nut (36)

terminal lug on end of wire (35) to stud. Reattach nut (36) and tighten to

secure wire (35).