TM 10-5410-228-24

3.10 AIR BEAM SHELTER (ABS).

This task covers:

a. Tears, Holes, Worn Areas

c. Buckles, Fasteners, and Webbing

b. Rivet or Grommet Rips

INITIAL SETUP

Tools/Test Equipment:

Equipment Conditions:

Drill, Electric (Item 6, Appendix B)

ABS deflated, detached from LMS (see para 2.13.3).

Drill Set (Item 5, Appendix B)

Goggles (Item 17, Appendix B)

Materials/Parts:

Marking Chalk (Item 16, Appendix C)

Riveter, Blind, Hand (Item 34, Appendix B)

Blind Rivet (Item 82, Appendix E)

Sewing Machine (Item 37, Appendix B)

Electric Sealing Iron (Item 36, Appendix B)

References:

ABS Repair Kit (see TM 10-5410-228-10)

TM 10-5410-228-10

NOTE

Major tears and holes should be repaired using a sewing machine. Small hand sewn repairs

should be permanently repaired as soon as possible.

No attempt has been made to identify all fabric repair procedures. Procedures provided

herein are representative in nature. Repair materials can be found in the ABS repair kit.

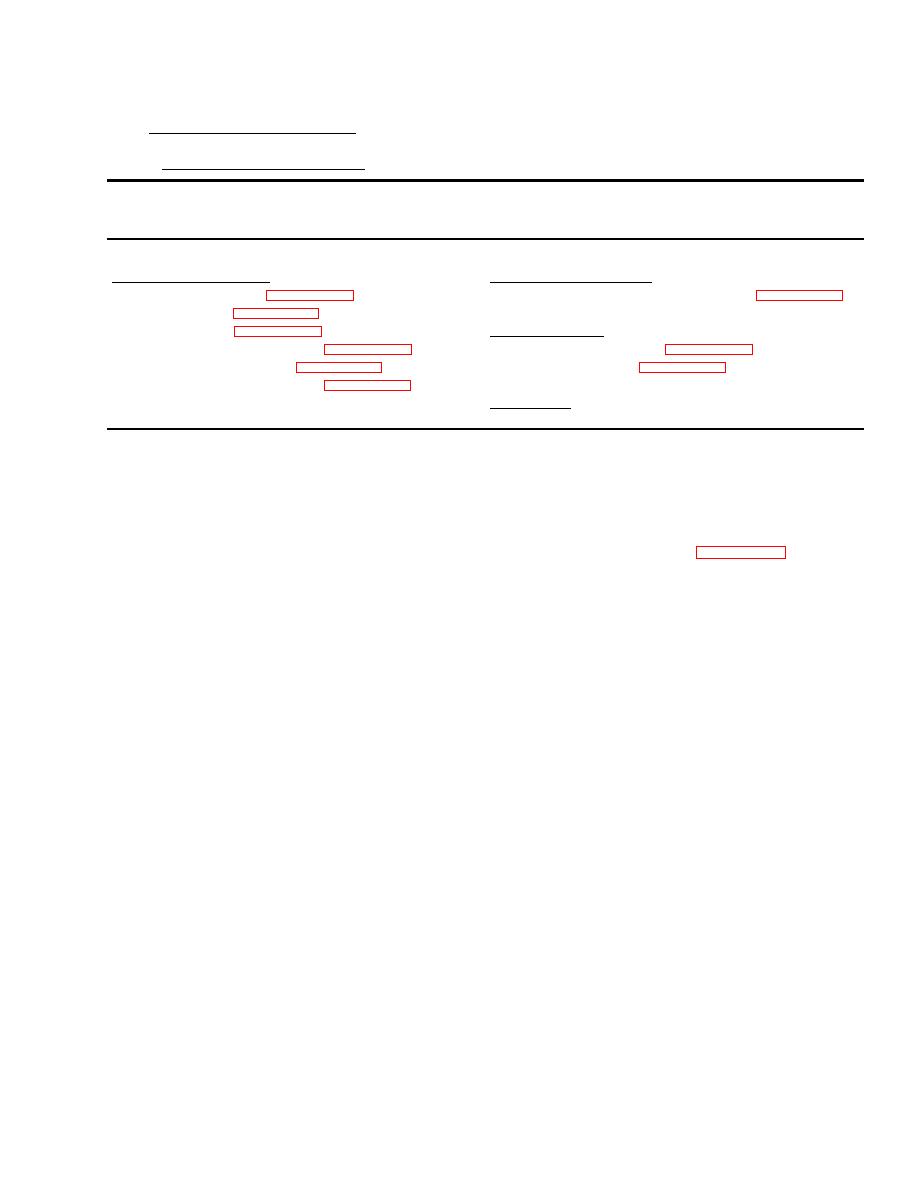

a. Tears, Holes, Worn Areas of Travel Covers and Insulated Liner Only (Refer to Figure 3-28) (for

repairs to ABS fabric, reference TM 10-5410-228-10).

(1)

Measure damaged area.

(2)

Cut patch from matching fabric making sure that the patch is large enough to extend 2-3/4

inches beyond damaged area (1) on all four sides.

(3)

Fold patch in half lengthwise (2) and crease fold.

(4)

Unfold patch and fold top left-hand corner (3) to crease in center.

(5)

Fold right-hand corner (4) to crease in center aligning right corner with left corner.

(6)

Fold inside corner (5) of each triangle to edge of outside fold.

(7)

Patch should look like (6). Crease folds in place.

(8)

Cut off top fold (7) from patch (6).

(9)

Turn patch face up and draw chalk line 3/4 inch from edges of patch (8).

(10) Turn patch over and fold edges along chalk lines inward. Crease fold.

NOTE

Use single needle industrial sewing machine with compound feed and high-lift alternating

pressure to sew fabric.

Slanted edges of patch should point towards direction of water run off.

(11) Place fabric and patch on sewing machine and sew patch by stitching a seam 1/8 inch from the

folded edges (9). Tack first seam by stitching over first stitches by at least 1 inch.

(12) Sew second seam 3/8 inch to 1/2 inch inside the first seam. Tack second seam by stitching over

first stitches by at least 1 inch.

(13) Cut out damaged area on inside of fabric to within 1/8 inch of second seam.