T.O. 33B-1-1

6-4

6.1.2.1.2

NOTE

Although radiography will reveal the interior of opaque objects, it cannot detect all

types of irregularities or discontinuities. Small defects in thick objects such as fine

cracks or indentations are difficult to detect. In applying radiography as an

inspection method, the sensitivity of the method must be kept in mind. The

limitations of radiography will become more apparent in subsequent discussions.

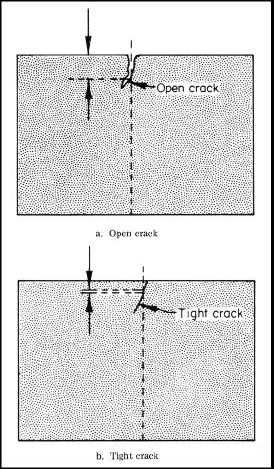

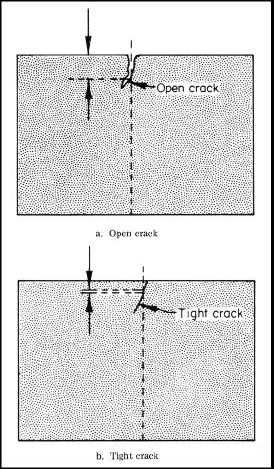

Some voids are difficult to detect, because they present a very slight change in material thickness to a beam of

radiation. A most important example of this type of defect is the crack. A crack represents a tear or rupture within a

homogeneous material. If a crack is open, that is, the opening is wide, (see Figure 6-3a) it appears to the radiation

beam as a significant change in effective material thickness and is thus readily detected. However, if a crack is under

compression and is very tight as illustrated in Figure 6-3b, then its detection may become very difficult, if not

impossible, because the apparent change in material thickness is negligible. It is important to note that crack

orientation also has a very significant effect on the detectability of the crack with radiation. In Figure 6-3b, if the crack

were oriented parallel with the radiation beam, the effective change in material thickness would be enough to make the

crack easily detectable. However, in most situations the probability of aligning a beam with a tight crack is low, so

other NDI techniques must be relied upon as backups. The problems associated with crack detection will be dealt with

at length in later paragraphs.

Figure 6-3. Effect of Change in Thickness of Cracks.