T.O. 33B-1-1

4-12

4.2.2.2

Effects Of Inspection Conditions on Eddy Currents.

4.2.2.2.1

Frequency.

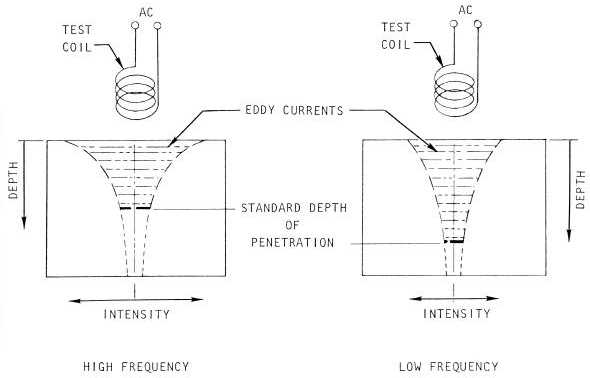

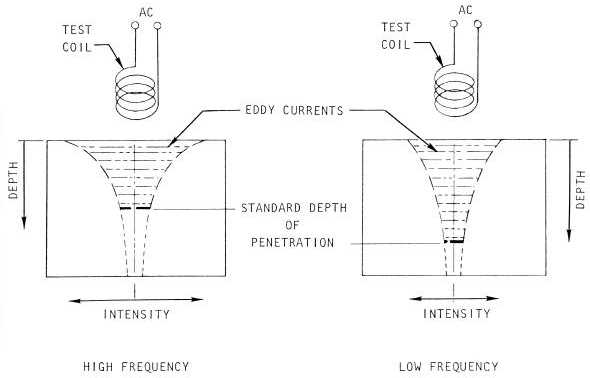

The magnitude of the induced eddy currents in the part increases as the frequency of the inducing current increases. In

turn, the higher intensity eddy currents generate a stronger opposing magnetic field, reducing the penetration of the

primary field. Therefore, all other factors remaining constant, higher frequencies result in shallower depths of

penetration as shown in Figure 4-9.

Figure 4-9. Relative Effect of Frequency on Depth of Penetration.

4.2.2.2.2

Electromagnetic Coupling.

The interaction between the primary electromagnetic field, generated by the coil and the inspection article is referred to

as electromagnetic coupling. Because the field decreases in strength with increasing distance from the coil, resultant

eddy currents at the surface of the part will also decrease in intensity. An electrical engineering term that could also be

used is inductive coupling.

4.2.2.2.3

Lift-Off.

As an eddy current probe is brought near a conductive part, a change in the detected signal will be noted. With the

probe near a part, a pronounced signal change will be observed in response to a small change in distance between probe

coil and part. This effect is termed lift-off. The signal change occurs because the intensity of the eddy currents in the

part decreases considerably with a slight increase in coil-to-part spacing. This condition is demonstrated in Figure 4-

10. Calibrated measurements of lift-off can be used to determine the thickness of nonconductive coatings on conductive

parts.