T.O. 33B-1-1

4-9

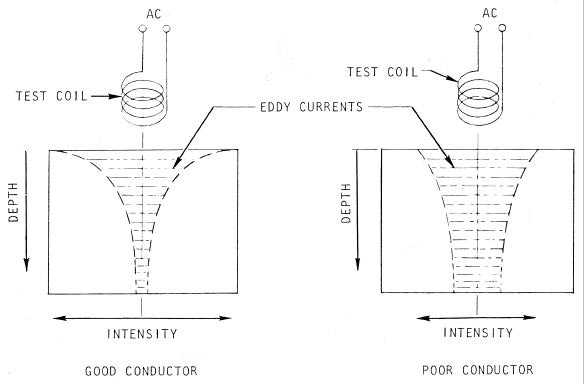

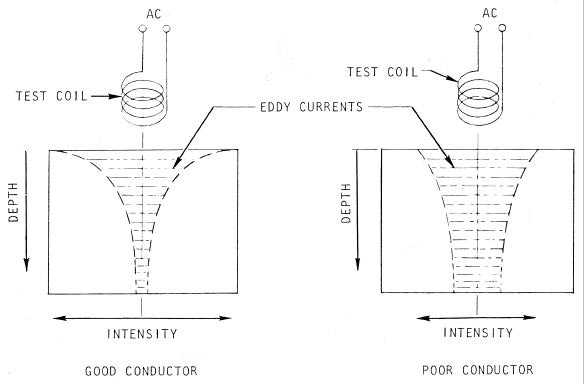

Figure 4-4. Relative Magnitude and Distribution of Eddy Currents in Good and Poor Conductors.

4.2.2.1.2

Permeability.

In a ferromagnetic material, as compared to a non-ferromagnetic material, the primary field results in a much greater

internal field because of the large relative magnetic permeability. The increased field strength at the surface results in

increased eddy current density. The increased eddy current density generates a larger secondary field that rapidly

reduces the overall field strength a short distance from the surface. Consequently, the effective depth of penetration

during eddy current inspection is much less in ferromagnetic materials than in other conductive materials. The high

relative magnetic permeability acts as a shield against the generation of eddy currents much below the surface in a

ferromagnetic part. Thus, eddy current testing of ferromagnetic parts is usually limited to testing for flaws or other

conditions that exist at or very near the surface of the part. The relative effects of permeability variations on the depth

of penetration and the intensity of the eddy currents are shown in Figure 4-5.

4.2.2.1.3

Geometry.

Eddy currents, as generated by most eddy current inspection techniques, occupy a volume in a conductive material that

is relatively small. As indicated in Figure 4-4 and Figure 4-5, the volume is approximately conical and not very deep.

The maximum diameter will be on the order of twice the diameter of the driving coil and the depth is estimated by the

equation discussed in paragraph 4.2.3.3. Part geometry only becomes significant when this volume exceeds the volume

available within the part. This happens when the thickness of the region of the part inspected is less than the effective

depth of this conical volume or when an area near edges of the part is inspected.