T.O. 33B-1-1

3-9

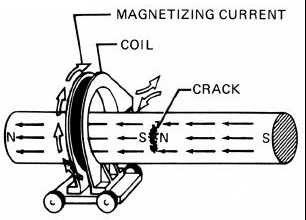

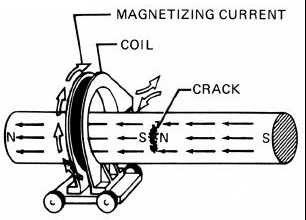

Figure 3-14b. Longitudinal Field produced by the Coil Generates an Indication of Crack in Part.

3.1.6.8

Multi-Directional Magnetic Field.

Two separate fields, having different directions, cannot exist in a part at the same time. However, two or more fields in

different directions can be imposed upon a part sequentially in rapid succession. When this is done, magnetic particle

indications can be formed when discontinuities are located favorably with respect to the directions of any of the applied

fields, and will persist as long as the rapid alternations of field direction continue. This enables the detection of defects

oriented in any direction in one operation. The indications must be viewed when the fields are being applied because

they are weakly held after the current is discontinued and can be easily dislodged.

3.1.6.9

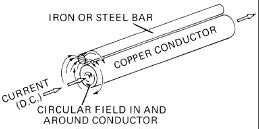

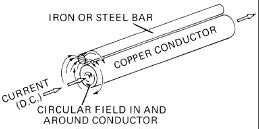

Parallel Current Induced Magnetic Field.

If a ferromagnetic bar is placed alongside, and parallel to, a conductor carrying current, a field will be set up in the bar

that is more transverse than circular (see Figure 3-15). Such a field is of very little use for magnetic particle testing.

Operators have tried to use this method as a substitute for a headshot for the purpose of producing circular

magnetization. The field produced is not circular and is extremely limited in the transverse direction when inspecting

for defects such as seams. Furthermore, the external field around the conductor and the bar can attract magnetic

particles and produce confusing backgrounds.

Figure 3-15. Field produced in a Bar by a "Parallel" Current

3.1.7

Current Sources For Generation Magnetic Field.

There are specific types of current used in magnetic particle testing. They are Straight Direct Current (DC); Single

Phase Alternating Current (AC); Three Phase AC; Half Wave Rectified Alternating Current (HWRAC or HWDC); Full

Wave Rectified AC; and Three-Phase Full Wave Rectified AC (commonly known as DC). Of these, three types of

magnetizing current are most often used in magnetic particle inspection. Only one type is generally best suited for each

type of inspection to be performed. Alternating current (AC) is preferred for the detection of surface discontinuities.

Direct current (DC), full-wave direct current, or half-wave direct current (HWDC) can be used for both surface and

subsurface discontinuities.