TB 750-651

d. Inspect for coolant cleanliness by withdrawing a small amount of coolant into a

clean and clear container. Look for rust, foreign particles, and/or sediment. Drain, clean,

and flush any cooling system that is contaminated. Look inside the radiator to see if the

flow tubes are clean. If not clean, use cleaning compounds listed in Table III.

8. Use of Engine Cooling System Cleaning Compounds

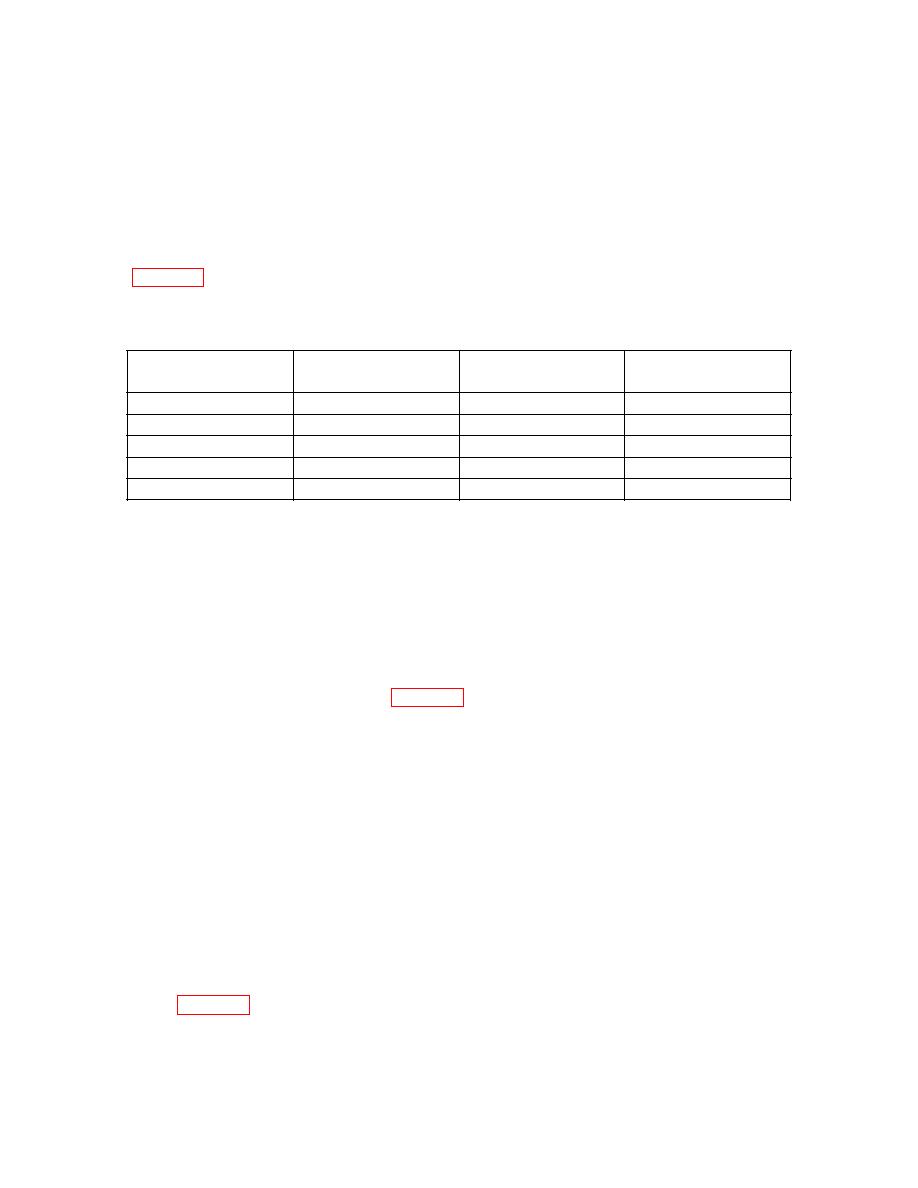

Table III. Cleaning Compounds

Part Number

Container Size

NSN

Cleaning

Compound

Alkaline

CC2610

1 Gal

Alkaline

CC2611

5 Gal

Alkaline

CC2612

55 Gal

Acid

CC2638

1 Gal

Acid

CC2637

55 Gal

NOTE

Do not use acid cleaner and Alkaline cleaner together. Mixing acid cleaner and

Alkaline cleaners will lose effectiveness to clean radiator. Use acid cleaner

first for removal of scale, corrosion, and oil fouling. Use Alkaline cleaner for

removal of silicate gelation. Removal of silicate gelation is the primary

use of Alkaline cleaner. All other uses provide marginal results.

Use cleaning compounds listed in Table III when necessary to clean heavily rusted or

partially clogged cooling systems. A 10% solution is suitable for most requirements

(1 Gal of cleaner mixed with 9 Gal of water). A 20% solution may be used for heavy

corrosion and scale deposits (2 Gal of cleaner mixed with 8 Gal of water).

9. Recycling of CID A-A-52624 Antifreeze

a. Recycling of used antifreeze conserves resources, reduces the cost of new

antifreeze purchases, and reduces the cost and problems of used antifreeze disposal.

b. An Antifreeze Recycling User's Guide is available from the U.S. Army

TARDEC/RDECOM (POLhelp@tacom.army.mil). The User's Guide provides product

recommendations, operating procedures, and precautions.

c. Currently, two antifreeze recycler units are approved for Army use. Their features

are in Table IV. You should base your selection of an antifreeze recycler system on your

organization's needs and resources.

7