TB 750-651

Table IV.

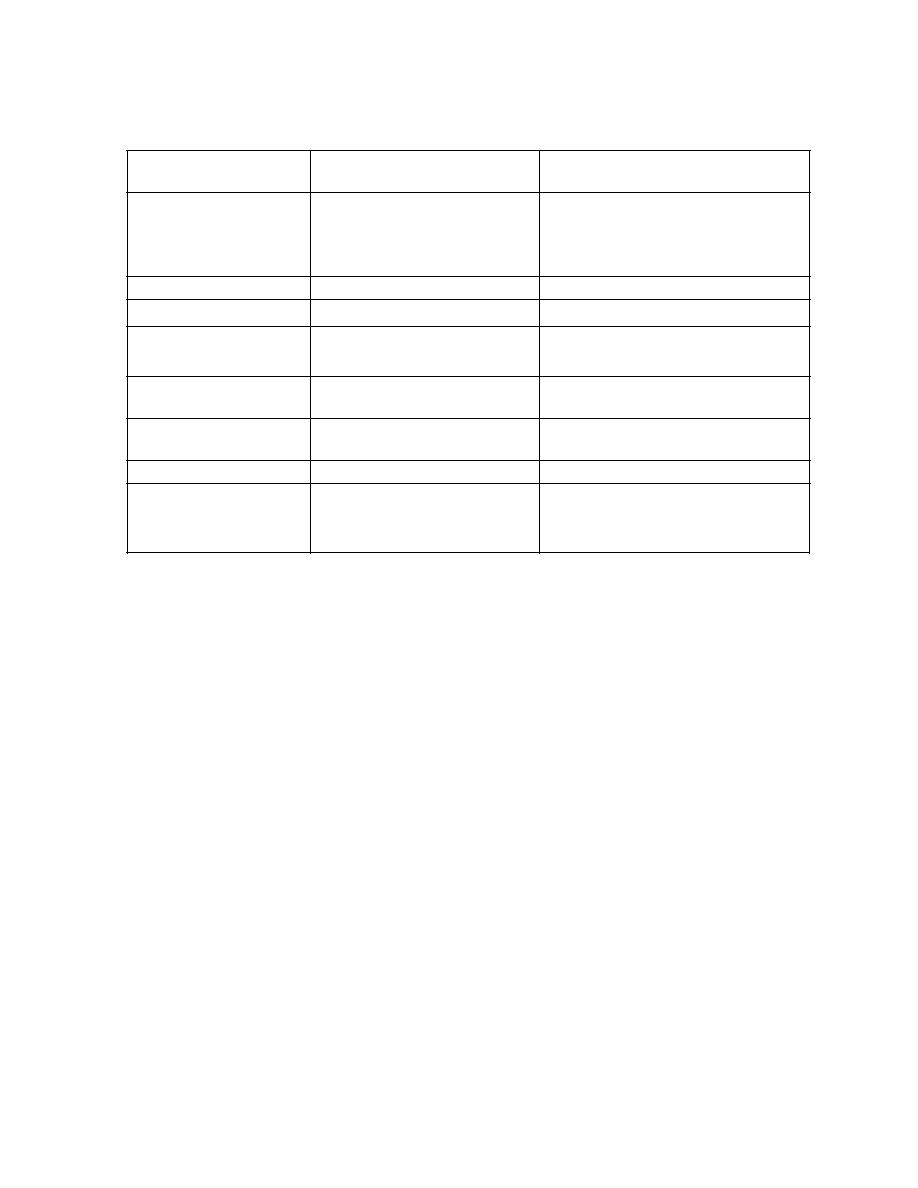

Commercial Antifreeze Recyclers

KFM Coolant Purification

BE-series Engine Coolant

Model

System (CPS)

Recyclers

KFM, LLC

Finish Thompson, Inc.

506 Camson Road

921 Green Garden Road

Manufacturer

Anderson, SC 29625

Erie, PA 16501

Phone: 800-736-1404

Phone: 800-888-3743

Ion-Exchange

Vacuum Distillation

Process Type

180 Gal/hr

3.06-3.44 Gal/hr

Process Rate

Yes. 1 & 5 micron

None

Replacement Filter

Required

Every 200-500 gallons

N/A

Filter Replacement

Interval

570 P & 570 K

J104016 (5 Gal) or

Additive Required

J103447 (55 Gal)

Moderately Difficult

Moderately Difficult

Ease of Operation

Liquid waste (EG/PG) broken

Hazardous Waste

Used filters

down corrosion inhibitors, dye,

Remaining

dirt, heavy metals, etc.

d. Other type of recyclers may not adequately recycle CID A-A-52624 antifreeze or

may create incompatibility with CID A-A-52624 antifreeze. These incompatibilities will

lead to increased cooling system maintenance and possibly premature failure of water

pumps, heater cores, and other cooling system components. These recyclers need to be

evaluated using the testing protocol provided in the Army's Antifreeze Recycling User's

Guide mentioned in Section 9.b.

10. Recording

a. When cooling systems have CID A-A-52624 or original antifreeze comes with the

vehicle (when the equipment is still under warranty) users must verify that the freeze

protection and corrosion protection are correct to ensure the engine's coolant protection.

Record the date and the degree of protection in the "remarks" block of DD Form 314.

b. When cooling systems are serviced with fully formulated CID A-A-52624

antifreeze, record the degree of protection and the condition of the cooling system. Drain

and replace with fresh coolant if and when necessary.

11. References

a. Forms

DD form 314

Preventive Maintenance Schedule and Record

DA Form 2028

Recommended Changes to Publications and Blank

b. Technical Manuals

TM 750-254

Cooling Systems: Tactical Vehicles

8