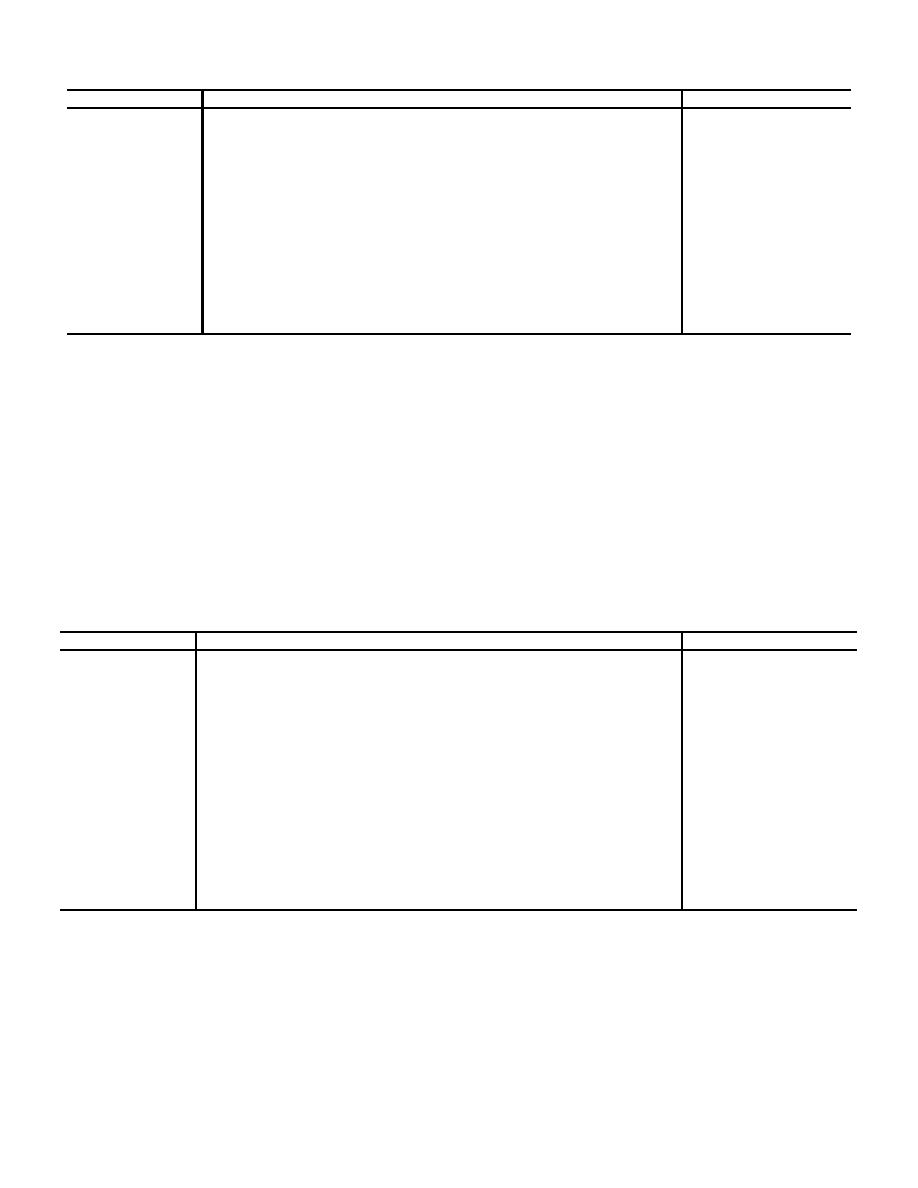

Table 1. Initial Receipt Inspection

Categories

Defect

Inspection Methods

Critical:

1

Item, packing or packaging damaged to the extent that hazardous

Visual

chemicals are exposed.

Major:

101

Lot count incorrect

Visual

102

Documentation missing or incomplete

Visual

103

Item damaged

Visual

104

Packing, preservation or packaging damaged to the extent that

Visual

adequate protection is no longer afforded to the item or handling

and storing would be adversly affected.

105

Item, packing or packaging contaminated, wet or mildewed

Visual

Minor:

201

Slight damage to packing or packaging.

Visual

9.2.2 Sampling. Sampling shall be performed on a lot

9.1.4 Reporting. Initial receipt inspection shall be

by lot basis utilizing the sampling plan provided in the

reported on DA Form 984 in accordance with the

applicable storage serviceability standard.

provisions of this bulletin and the applicable storage

serviceability standard for the item. Ir. addition, failure

9.2.3 Examination and test. When the serviceability

data and/or discrepancies encountered will be reported

on DD Form 1686 (Report of Deficiencies Found in

status is unknown the examination and test(s) shall be

Materiel) in accordance with TB 750-94-2.

performed in accordance with the classification of

defects and test requirements provided in the applicable

9.2 Prestorage Inspection (PS).

storage serviceability standard for the item. All lots shall

be examined for receipt condition utilizing the following

table.

an occurrence basis.

Table II. Prestorage Inspection

Categories

Defects

Inspection Methods

Critical:

2

Item, packing or packaging damaged or deteriorated to the extent

Visual

that hazardous chemicals are exposed.

Major

107

Lot count incorrect

Visual

108

Documentation missing or incomplete

Visual

109

Item damaged

Visual

110

Item, packing or packaging contaminated wet or mildewed as a

Visual

result of adverse shipping conditions.

111

Packing or packaging damaged to the extent that adequate protection

Visual

is no longer afforded to the item or handling and storing would be

adversely. affected.

112

Preservation, packing, packaging or marking incorrect.

Visual

Minor-

202

Slight damage to packing or packaging

Visual

9.2.4 Reporting. Prestorage inspection shall be reported

headquarters or instructions provided locally when it is

deemed necessary to satisfy local installation

on DA Form 984 in accordance with the provisions of

requirements.

this bulletin and the applicable storage serviceability

standard for the item.

10. Coded Standards. The following is an explanation

9.3 Periodic Cycle (P) and Pre-Issue Inspection (PI).

by heading of the codes used in the Coded Standard

These inspections shall be performed in accordance

with the requirements of the applicable storage

serviceability standard for the item.

9.4 Special Inspection (S). This inspection shall be

performed in accordance with the direction given by

5