TM 5-3740-214-14

COMPRESSOR MAINTENANCE (Continued)

(d) Set the pulsation tank in place between the heads and screw the mounting bolts down but not tight.

(e) Lightly torque each head bolt.

NOTE

Torque the longer center bolts first then the shorter outside bolts.

(f) Torque the head bolts to 400 in-lbs (4.61 kgM).

(g) Torque the pulsation tank bolts to 400 in-lbs (4.61 kgM).

NOTE

When new gaskets are installed, retorque the head bolts to 400 in-lbs (4.61 kgM) after 5 hours of

operation.

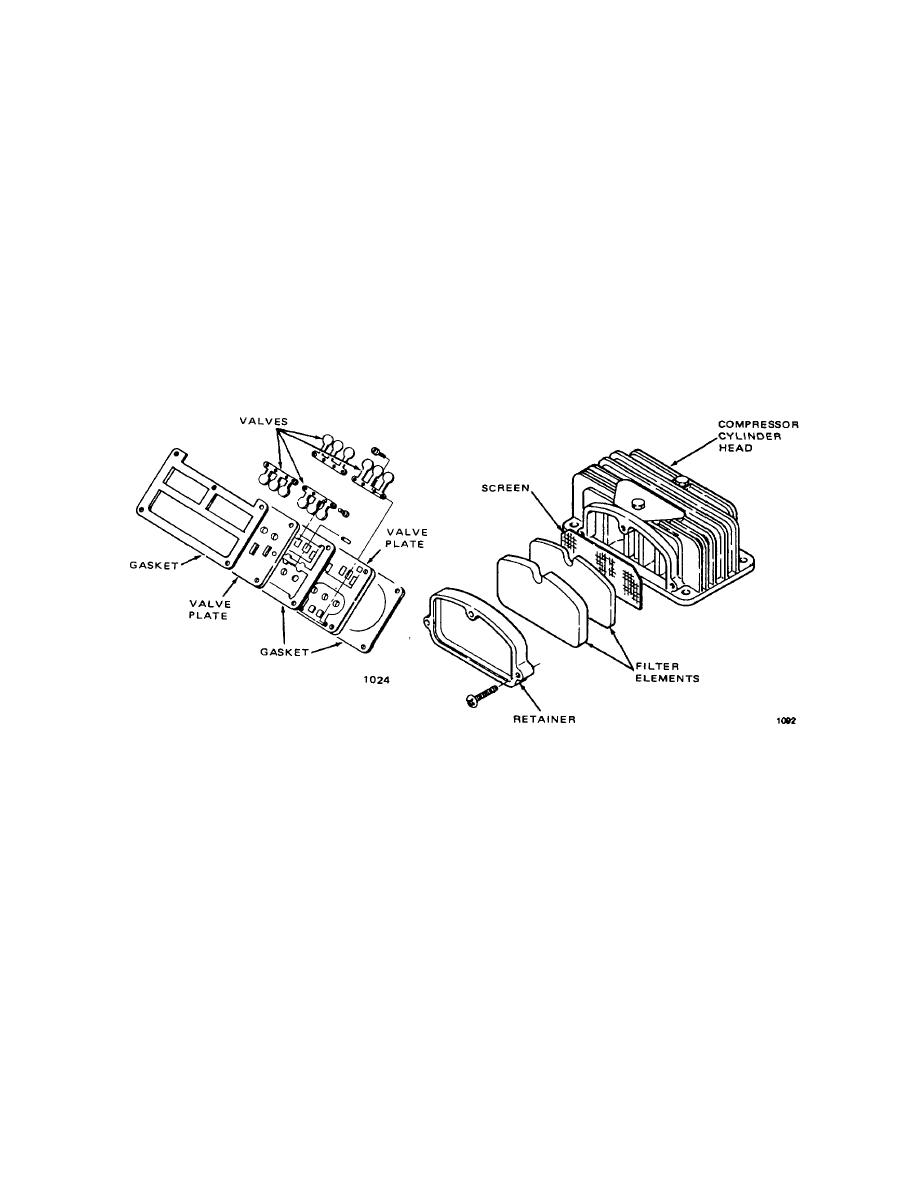

Figure 5-263. Compressor Valve Plate Assembly

(h) Install air hose fitting drain valve and separator pipe in pulsation tank.

(i) Install air filter elements screen and filter retainer in compressor heads.

(3) Assemble separator assembly.

NOTE

Retighten separator pipe pipe elbow nipple and separator assembly after the compressor reaches

its normal operating temperature.

(a)

Attach elbow and nipple to pulsation tank.

(b)

Attach separator cap to nipple.

(c)

Attach pressure relief valve to separator cap.

(d)

Attach stud, filter element, baffle disc, and retainer nut to separator cap.

(e)

Attach gaskets, separator body, and separator base to separator cap with washer and nut.

(f)

Attach street elbow to separator. Be sure the street elbow is torqued tightly.

(g)

Attach separator drain valve to separator base.

5-238