TM 5-3740-214-14

COMPRESSOR MAINTENANCE (Continued)

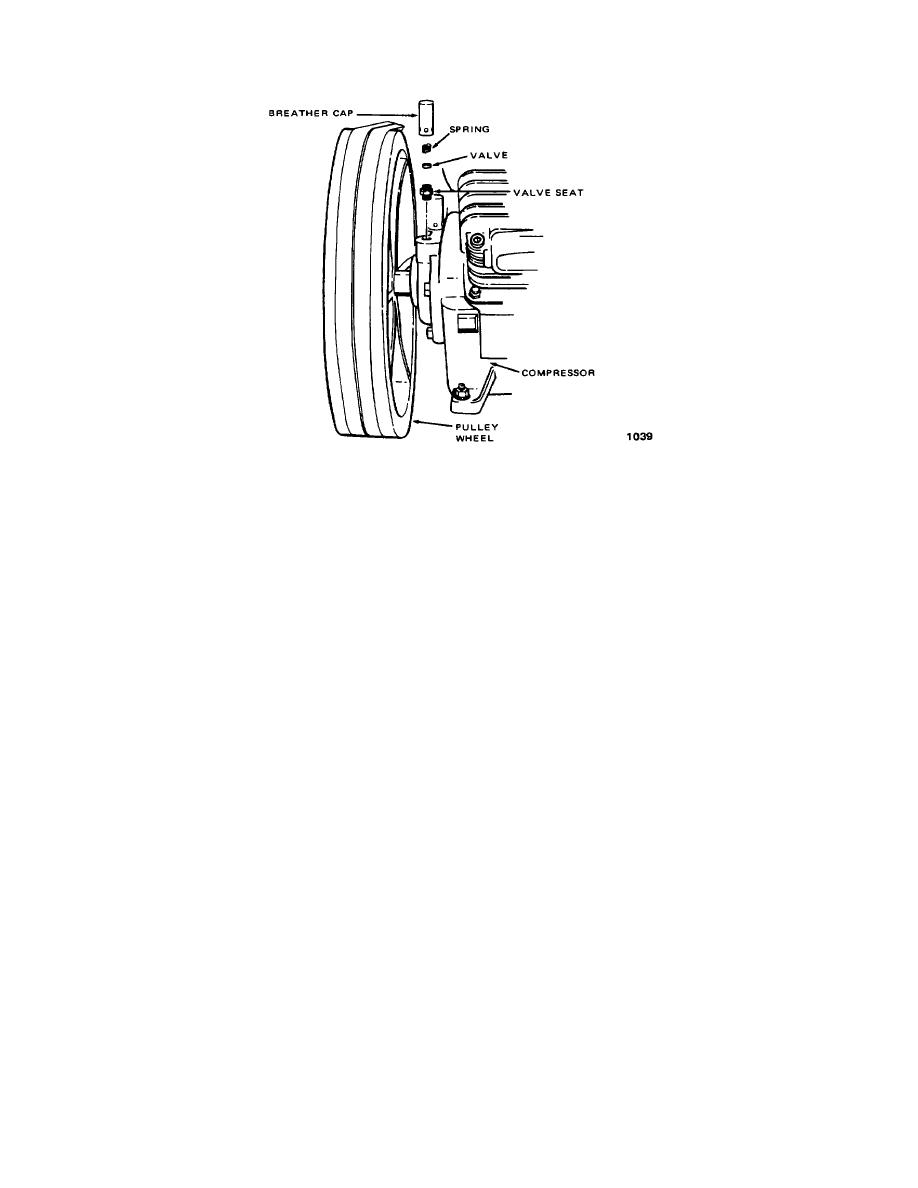

Figure 5-262. Compressor Breather Assembly

c. Clean and Inspect compressor.

(1) Cleaning. Clean all mud, grease and dirt from the outside of the compressor before disassembly using a

cleaning compound such as Federal Specification P-C-435A. Dilute the compound as recommended on its container.

Thoroughly clean all internal parts with cleaning compound such as MIL-C-11090D. Clean all bearings with dry cleaning

solvent P-D-680. When the bearings are clean, spin them in light lubricating oil to remove solvent VV-L-820-C.

(2) Inspection. Check all machined surfaces for nicks, cuts or scratches. Look for uneven wear on the

crankshaft. Make sure the bearings are not out of round or scarred. Replace any damaged parts.

d. Assemble compressor.

(1) Install breather assemblies.

(2) Install compressor head assemblies and pulsation tank.

NOTE

Install new valve plate gaskets, head gaskets, and pulsation tank gaskets when reassembling the

compressor.

(a) Assemble valve plate assemblies.

(b) Install valve plate assemblies.

(c) Install valve plate and head assemblies. Do not tighten the head bolts.

5-237