TM 5-3740-214-14

Table 3-2. Operator Troubleshooting

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1. NOZZLE PRESSURE GREATER THAN 100 PSI

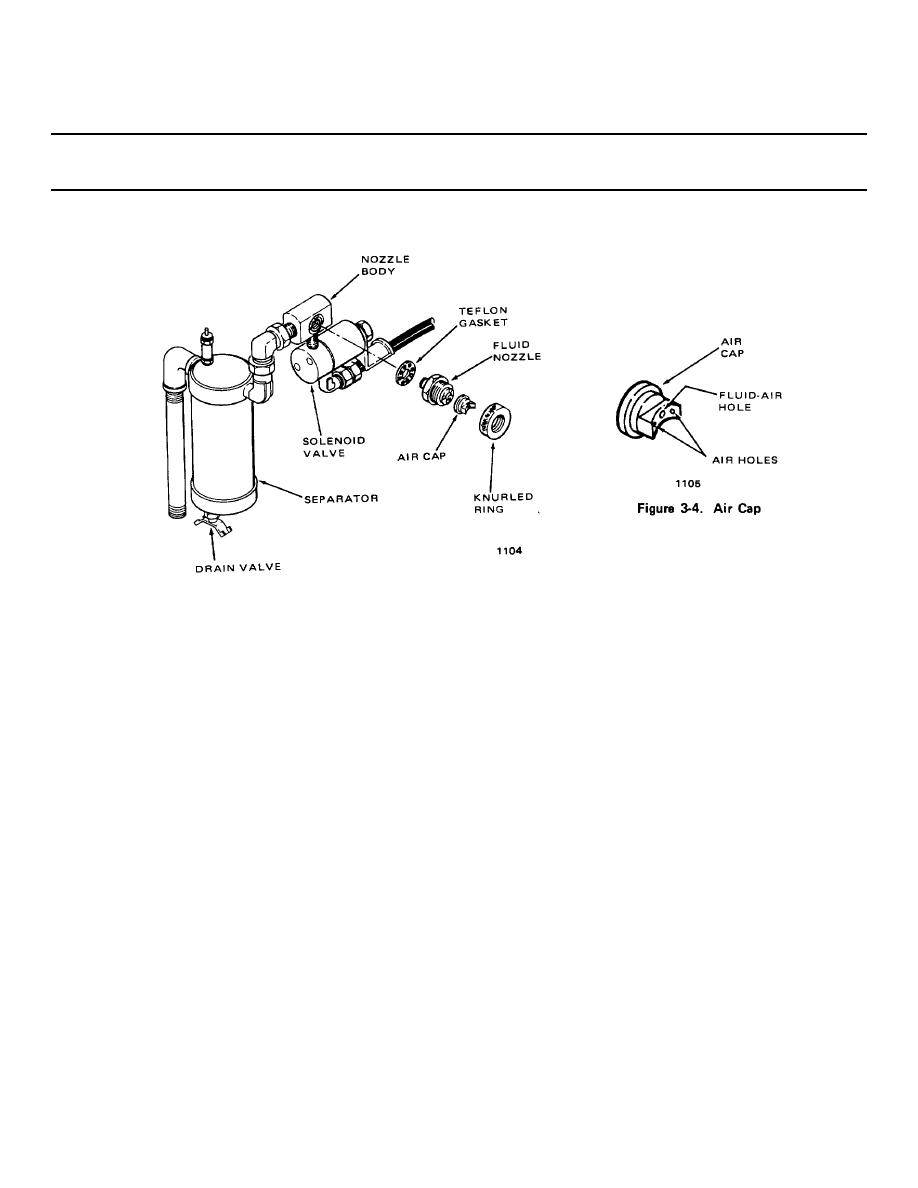

Figure 3-3. Nozzle Assembly

Step 1. Check nozzle assembly for blocking or plugging.

CAUTION

Do not use hard metal objects or probes to unplug air cap holes. Use a soft material like a

toothpick.

a. Unscrew the knurled ring and remove the air cap.

(1) If the air cap holes are partially or completely plugged or coated with oil residue,

soak the fluid nozzle in acetone (O-A-51F) to clean it.

(2) Carefully dean out the air cap holes with a toothpick or other non-metallic object.

(3) Wipe the air cap, the exposed fluid nozzle surfaces and the fluid hole projection

with a clean rag. Go to step 1b.

(4) If the air cap is not plugged, go to step 1b.

b. Remove the fluid nozzle and check the air holes.

(1) If the air holes are plugged, or coated with oil residue, soak the fluid nozzle in

acetone (O-A-51F) to dissolve the gunk and varnish.

3-4