TM 5-3740-214-14

Table 3-2. Operator Troubleshooting (Continued)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

NOZZLE PRESSURE GREATER THAN 100 PSI (Continued)

c. Reassemble the nozzle assembly and turn the engine ON. Check the pressure gage.

(1) If the pressure is 90-100 psi, the problem is solved.

(2) If the pressure is still greater than 100 psi, notify your supervisor of the problem.

2. NOZZLE PRESSURE BELOW 90 PSI

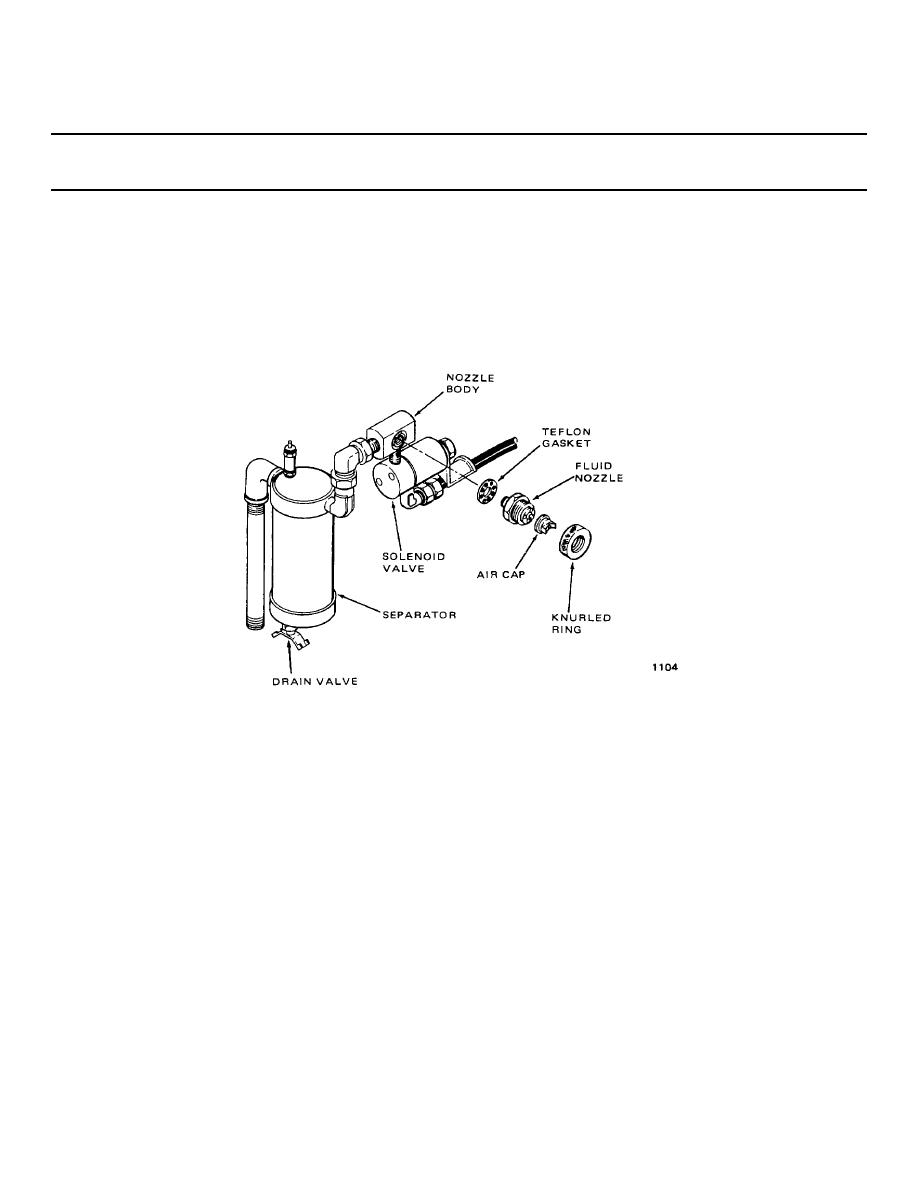

Figure 3-7. Nozzle Assembly

Step 1. Turn the engine ON and listen to the compressor.

a. If it runs smoothly, it is ok.

b. If the compressor makes grinding, rubbing or rattling noises, stop the engine and

notify your supervisor.

Step 2. Check the nozzle assembly parts listed below for air leaks:

1.

Knurled ring

2.

Fluid nozzle

3.

Teflon gasket

4.

Nozzle body

5.

Adjusting nuts and nipples

6.

O-rings

3-6