TM 5-3740-214-14

STARTUP AND OPERATION SUMMARY (Continued)

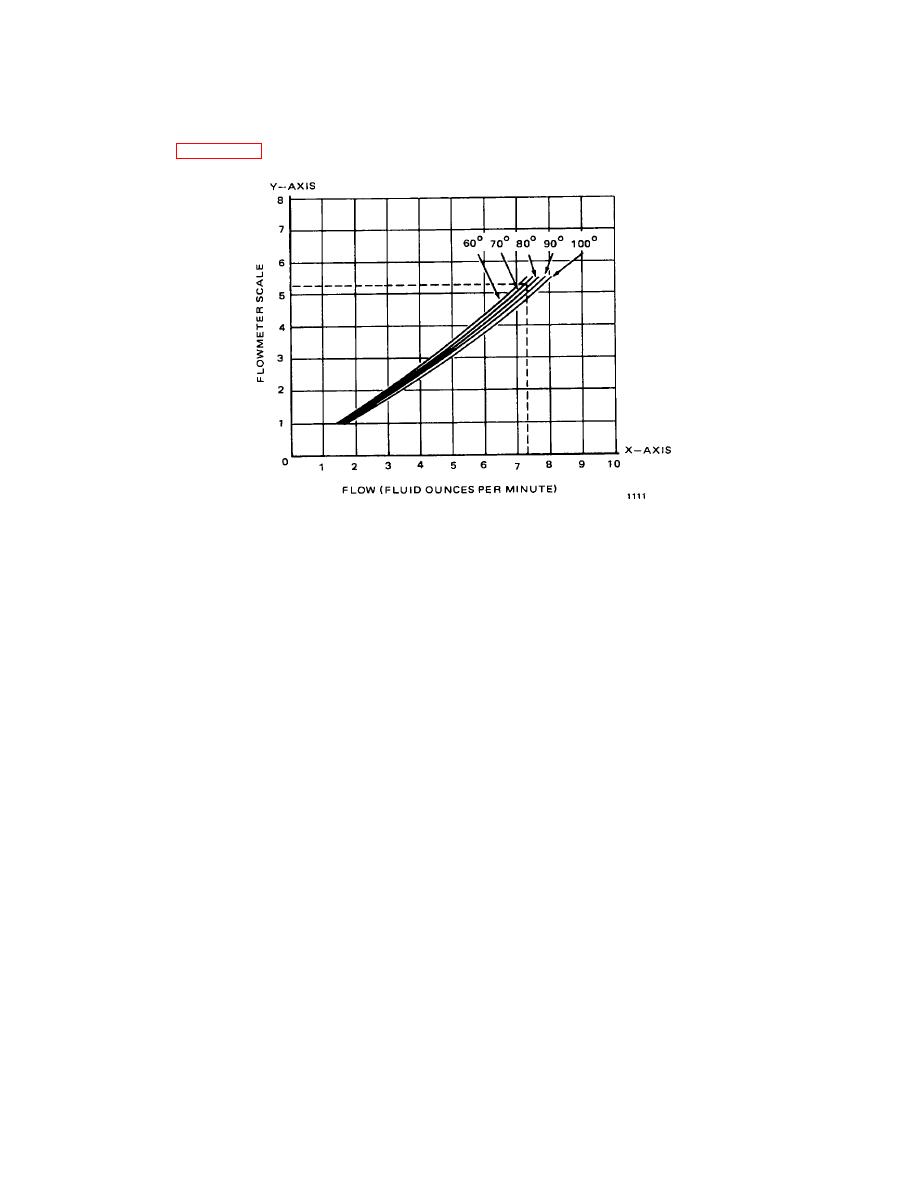

(6) Using the recorded flow rate and temperature, determine the insecticide flow rate in ounces per minute from the

appropriate graph. Figure 2-39 illustrates how to use the temperature correction curves.

Figure 2-39. Temperature Correction Curve

NOTE

Temperature correction curves are listed on pages 1-9 through 1-13 for EPA approved insecticides.

Refer to these curves for the appropriate insecticide flow rates.

(7) Allow insecticide to flow into a beaker for a timed minute.

(8) Turn OFF the ignition switch.

(9) Transfer the insecticide from the beaker into a graduated cylinder.

(10) Compare the reading determined from the temperature correction curve to the number of ounces per minute

collected in the beaker.

(11) If the flow rates are not equal, notify your supervisor.

f.

Operation Procedures

(1) Adjust the flowmeter to the proper flow rate.

(2) Check the insecticide label for the recommended driving speed.

(3) Drive over the course to be sprayed.

(4) Monitor the operation temperature and the operating nozzle temperature.

NOTE

A gradual increase in the nozzle operating pressure may be due to a build up of oil residue in the

nozzle. If corrective action outlined in the operator troubleshooting table does not correct the

problem, notify your supervisor.

2-35