TM 10-5410-228-24

b. Installation (Refer to Figure 3-16)

Ensure that O-ring is seated and retained properly. During installation, fitting threads can

damage O-ring causing leaks to occur.

(1)

For split flanged assemblies, install new O-ring on flange and position flange and clamp halves

on component.

(2)

Lubricate O-ring with light coating of hydraulic fluid.

(3)

Install new lockwashers on bolts and bolt through clamp halves.

(4)

Hand tighten bolts. Torque bolts in diagonal sequence in small increments to the appropriate

torque listed in the following table.

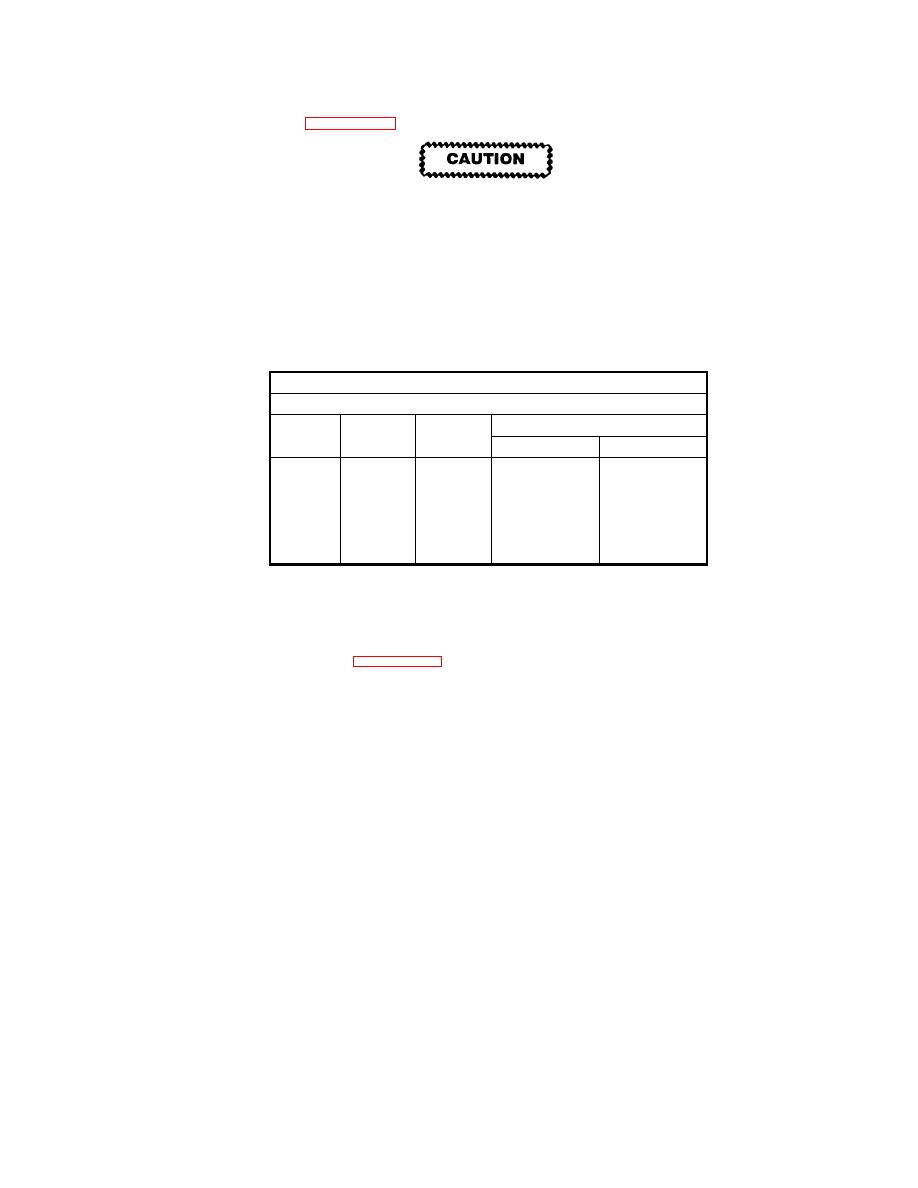

4-Bolt Split Flange

Code 61 Flange Adapter Recommended Bolt Torque

Dash

Flange

Bolt

Torque

Size

Size

Size

in.-lb

ft-lb

300 50

25 4.5

12

3/4

3/8 16

375 50

31 4.5

16

1

3/8 16

488 62

41 5

20

1 1/4

7/16 14

625 75

52 6

24

1 1/2

1/2 13

725 75

60 6

32

2

1/2 13

(5)

Secure hose by tightening by hand and then turning one flat using a wrench.

(6)

Install tie-down straps as required.

(7)

Install loop clamps with attaching hardware as required.

(8)

Add hydraulic fluid per para 2.14.3.

(9)

Run system for five minutes and check for leaks. Tighten fittings as necessary.

3-79