TM 10-5410-228-24

3.9.1

R22 Refrigerant System Servicing Continued.

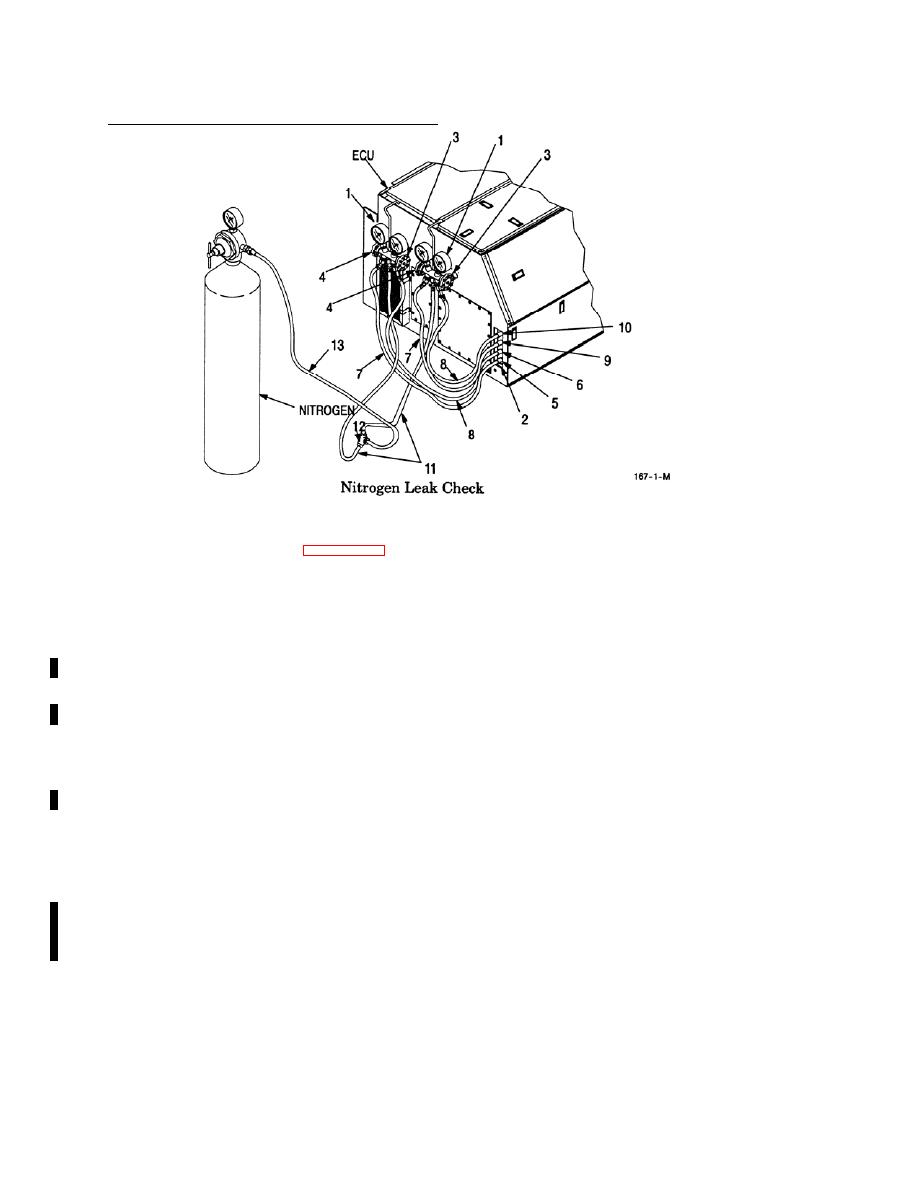

Figure 3-6. R22 Refrigerant System Servicing (Sheet 5 of 10)

e.

Checking for Leaks (Refer to Figure 3-6)

NOTE

Checking for leaks is normally done using a refrigerant gas leak detector prior to

maintenance actions. There must be approximately 100 psi of refrigerant in the system in

order to detect a leak by this method. If the system cannot be run, or all refrigerant has been

lost, checking for leaks is done using nitrogen and a vacuum as follows:

(1) Install two manifold gage sets, one to compressor service ports (5 and 6) and one to evaporator

service ports (9 and 10).

(2)

Make sure low pressure gage valves (4) and high pressure gage valves (3) are turned clockwise

to their closed (front seated) position.

(3)

Connect center hose (13) to bottle of nitrogen.

(4)

Set the nitrogen regulator to 150 psig, turn system on and pressurize system to 150 psig.

(5)

Turn manifold gage valves (3 and 4) counterclockwise to their open (full back seated) position.

(6)

Listen for leaks and use soap bubbles to locate any leaks.

(7)

If leaks are found, shut off nitrogen, bleed the system and repair all leaks.

(8)

Turn manifold valves (3 and 4) clockwise to their closed (full front seated) position.

(9)

Remove nitrogen bottle from center hose (13).

(10) Turn manifold valves (3 and 4) counterclockwise slowly until high pressure gages and low

pressure gages on manifolds (1) read zero.

(11) Remove tee (12) and connect the two manifold gage set center hoses (11) to vacuum pump.

(12) Turn manifold valves (3 and 4) counterclockwise to their open (full back seated) position.

(13) Pull vacuum down to 28 to 30 inches of vacuum.

3-34

Change 1