TM 10-5410-228-24

3.9.1

R22 Refrigerant System Servicing Continued.

Figure 3-6. R22 Refrigerant System Servicing (Sheet 3 of 10)

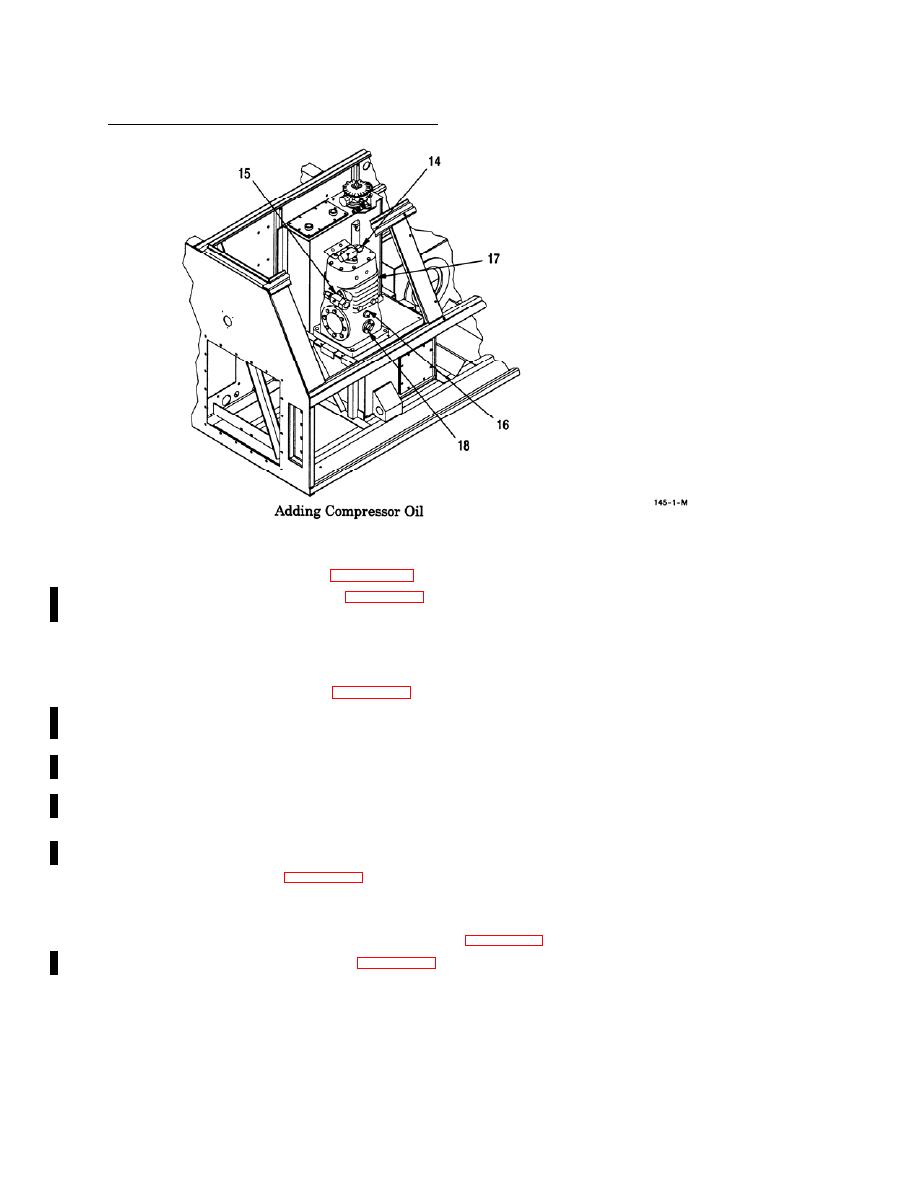

c. Adding Compressor Oil (Refer to Figure 3-6)

(1) Install manifold gage sets per para 3.9.1.a.

(2) Make sure low pressure and high pressure gage valves (4 and 3) on manifold gage sets (1) are

turned clockwise to their closed (front seated) position.

(3) Turn compressor service discharge valve (14) and compressor service suction valve (15)

clockwise to their closed (front seated) position.

(4) Recover R22 refrigerant per para 3.9.1.

(5) Turn low pressure gage valves (4) and high pressure gage valves (3) counterclockwise slightly to

permit R22 refrigerant in the compressor to slowly escape through center hoses (11) until gages

read 0 (zero).

(6) Close low pressure gage valves (4) and high pressure gage valves (3).

(7) Remove fill plug (16) from compressor (17).

(8) Add oil as necessary to attain proper level on sight gage (18).

(9) Install fill plug (16) on compressor (17). Tighten fill plug to 6-9 lb-ft.

(10) Check for leaks per para e. Connect gage sets to compressor service ports only.

(11) Evacuate system per para 3.9.1.d.

(12) Turn compressor service discharge valves (14) and compressor service suction valves (15)

counterclockwise to their open (back seated) position.

(13) If not already accomplished, charge system per para 3.9.1.

(14) Remove manifold gage sets per para 3.9.1.h.

3-32

Change 1