TM 10-5410-228-24

This task covers:

a. Removal

b. Installation

INITIAL SETUP

Tools/Test Equipment:

Equipment Conditions:

Shop Equipment, Automotive Maintenance and

ECU covers and doors opened or removed as

Repair (Item 38, Appendix B)

required (see para 2.14.1).

Shop Equipment: Electrical Equipment

ECU work platform installed (reference TM

(Item 40, Appendix B)

10-5410-228-10).

Gloves (Item 16, Appendix B)

Hydraulic system drained (see para 2.14.3).

Goggles (Item 17, Appendix B)

Multimeter (Item 27, Appendix B)

References:

TM 10-5410-228-10

Power Supply (Item 29, Appendix B)

1 Inch Deep Well Socket - 1/2 Inch Drive

Materials/Parts:

(Item 44, Appendix B)

Hydraulic Fluid (Item 24, Appendix C)

1-1/4 Inch Deep Well Socket - 1/2 Inch Drive

Wiping Rags (Item 39, Appendix C)

(Item 46, Appendix B)

1-1/4 Inch Crowfoot Wrench (Item 58, Appendix B)

1 Inch Crowfoot Wrench (Item 56, Appendix B)

Torque Wrench (Item 66, Appendix B)

The hydraulic system is pressurized. To prevent injury to personnel, gloves and eye

protection must be worn when working on hydraulic system.

NOTE

Remove/disassemble only to the extent necessary to remove or replace defective

assemblies/components. Use standard maintenance shop practices/procedures.

O-rings are pre-installed on each solenoid valve.

The solenoid valves are all similar. Removal/installation is typical.

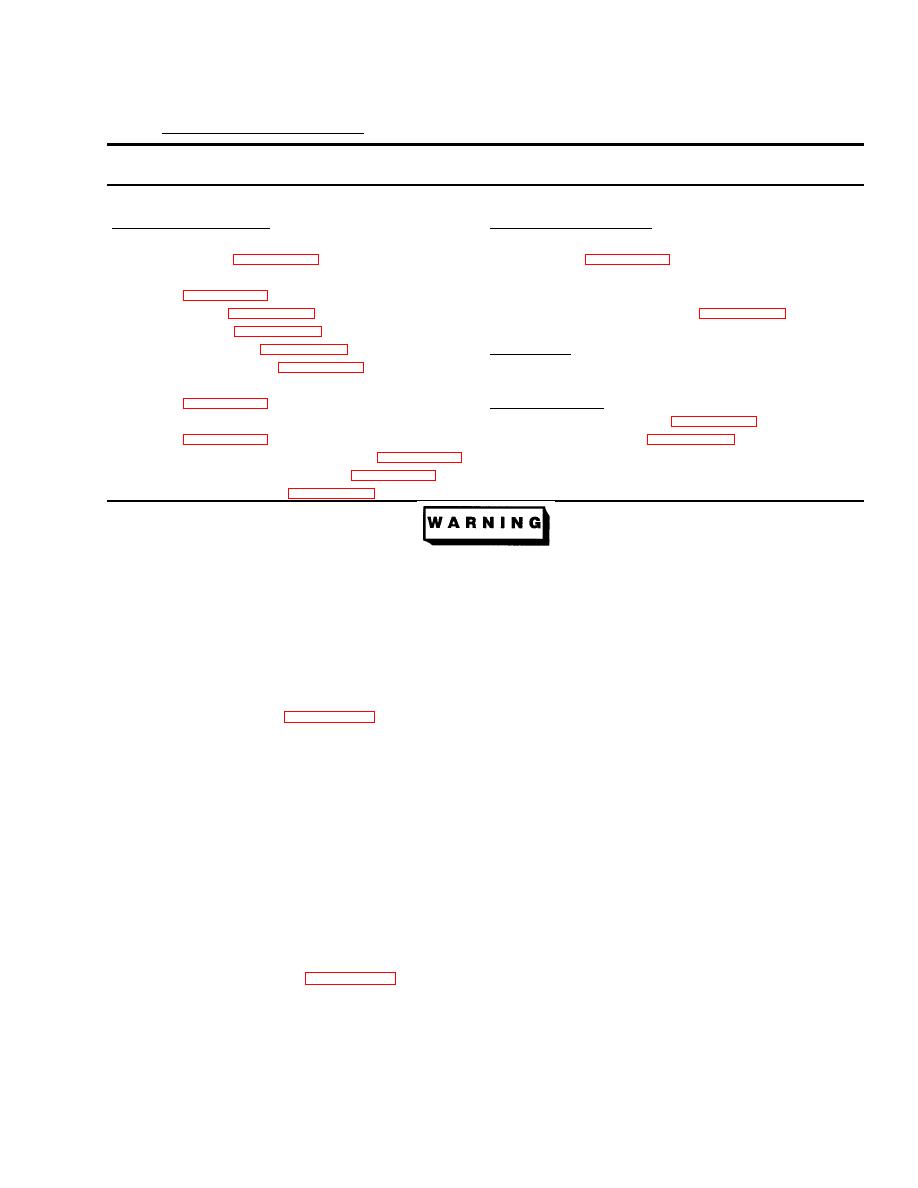

a. Removal (Refer to Figure 2-59)

(1)

Disconnect and tag cable assembly 1A4A1W3 connectors P12, P13, P8, P10, P3 and P15 from

solenoid valves SV1, SV2, SV4, SV5, SV6 and SV8 (respectively).

(2)

Remove nut (1) and actuator (2) of each solenoid valve SV1, SV2, SV4, SV5, SV6 and SV8.

Remove solenoid valve body (3) from hydraulic manifold (4).

(3)

Disconnect and tag cable assembly 1A4A1W3 connector P16 from solenoid valve SV7.

(4)

Remove nut (5) and actuator (6) of solenoid valve SV7. Remove solenoid valve body (7) from

hydraulic manifold (4).

(5)

Disconnect cable assembly 1A4A1W3 connector P14 from solenoid valve SV9.

(6)

Remove nut (8) and actuator (9) of solenoid valve SV9. Remove solenoid valve body (10) from

hydraulic manifold (4).

b. Installation (Refer to Figure 2-59)

(1)

Install solenoid valve SV9 body (10) in hydraulic manifold (4). Ensure that O-rings are seated

properly and not pinched. Tighten solenoid valve body (10) finger tight. Torque solenoid valve

body (10) to 25 ft. lbs.