T.O. 33B-1-1

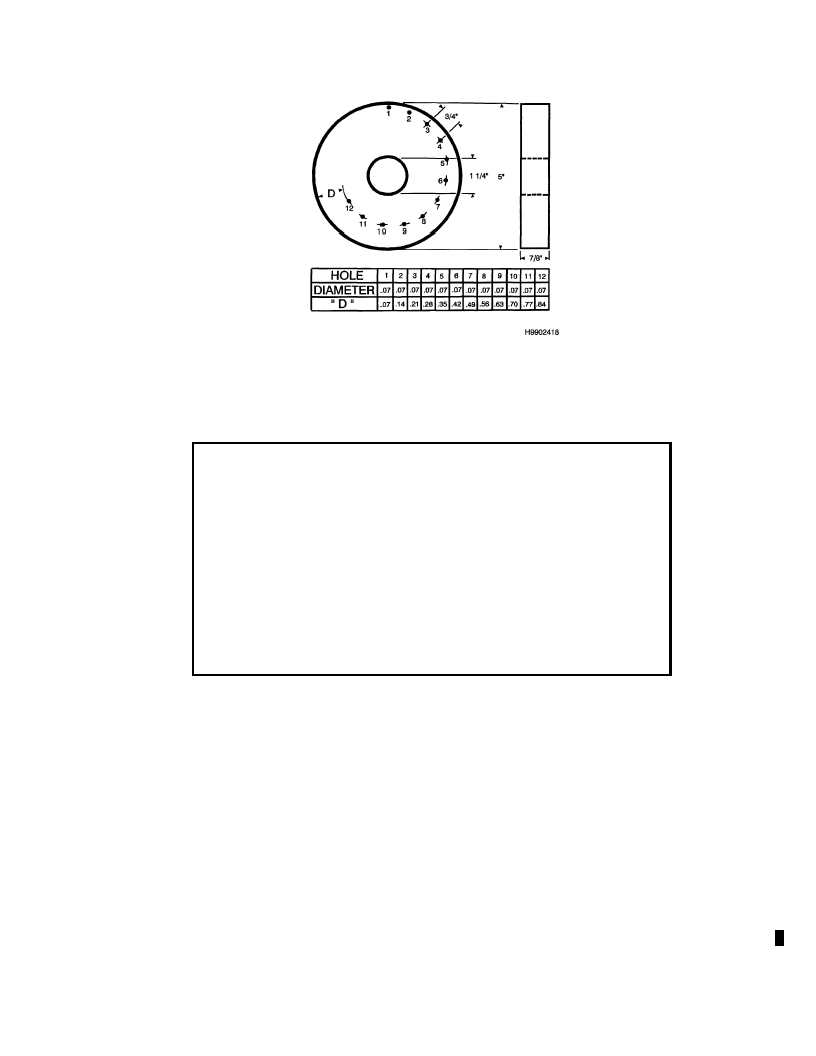

Figure 1-9.

Ketos Ring

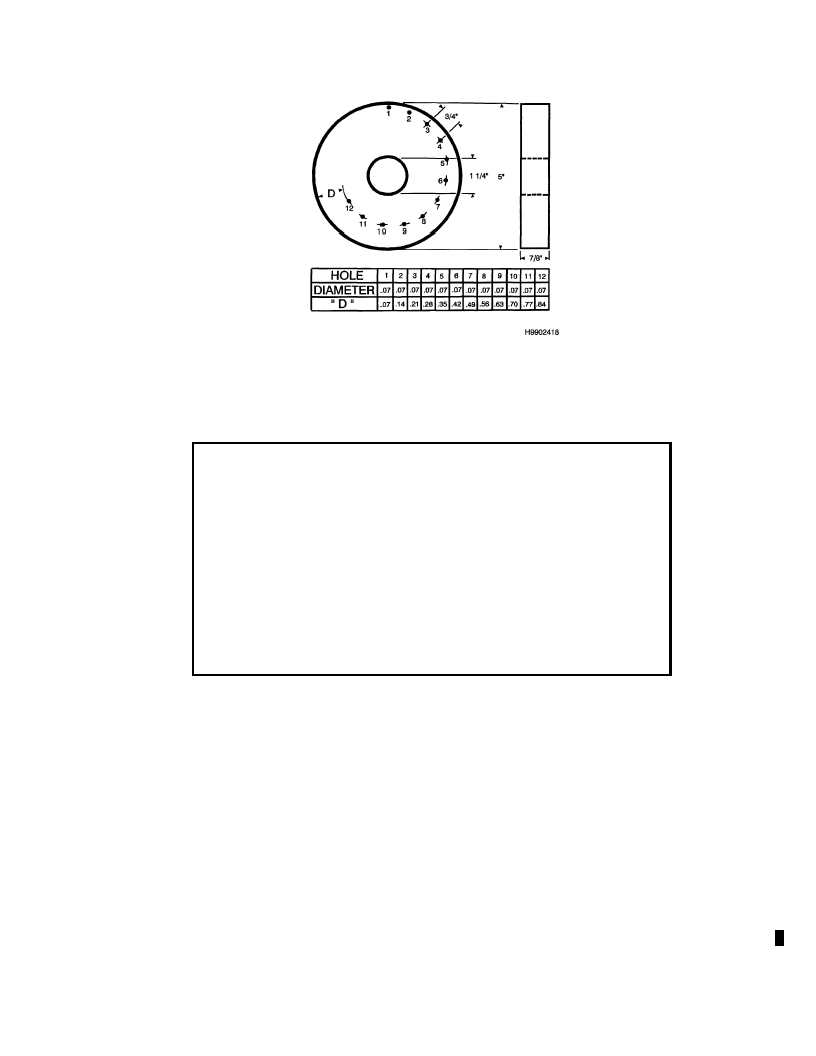

Table 1-4.

Ring Specimen Indications

Type of

D.C.

Minimum No. of

Suspension

Amperage

Holes Indicated

1400

3

Non-f luorescent

2500

5

3400

6

1400

4

Dry Powder

2500

6

3400

7

1400

3

Fluorescent

2500

5

3400

6

A.C. Amperage

Non-f luorescent

1000

1

Dry Powder

1000

1

Fluorescent

1000

1

1.6.10.2

QQIs.

Test specimen(s) used with QQIs offer a more versatile means of checking system performance than afforded

by the Ketos ring. The specimens can be real parts or designed to be representative of the most challenging

inspection to be currently performed. This combination is capable of providing an adequate check on any

magnetic particle inspection system. Even though QQIs respond to the applied, not residual, field,

demagnetization is necessary of the specimen(s) in order to remove the previously applied inspection media.

1.6.10.3

Cracked Parts.

The ultimate specimens for the performance tests are cracked parts. If available, they require careful

handling to remain corrosion-free and retain their f law sizes.

1.6.11

Ammeter Check.

Amperage indicator accuracy check SHALL be performed using the calibrated ammeter/shunt authorized in

TA-455. Operation of the ammeter/shunt SHALL be according to the commercial manufacturer’s operating

instruction. DC amperage variations exceeding 10% at reading or +60 amperes, whichever is greater, and

Change 2

1-49