T.O. 33B-1-1

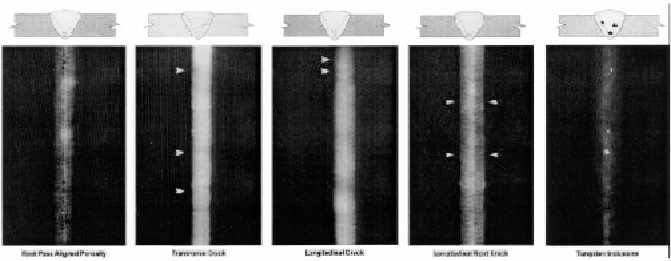

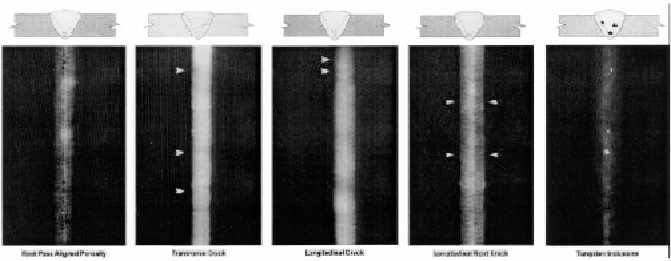

Figure 6-45.

Radiographic Examples of Welds (Sheet 2 of 2)

6.8.17.17

Aluminum and Magnesium Welds.

Radiographic technique and equipment for examining welds in aluminum and magnesium alloys are no

different than methods used for steel welds. The discontinuities produced by fusion welding of aluminum and

revealed on film by radiography include:

a.

Entrapped gas, ranging from fine gas porosity to large gas holes. The porosity may be in line or at

random.

b.

Inclusions of tungsten particles, foreign materials, f lux and oxide. Since the density of oxide films is

nearly the same as that of aluminum, they will not produce a detailed indication on a radiograph

unless present in large quantities.

c.

Inadequate penetration.

d.

Incomplete fusion.

e.

Cracks.

f.

Surface irregularities.

6.8.18

Spot Welds.

A special exposure technique is necessary for the inspection of spot welds. The welded areas are X-rayed with

a low-voltage, high-intensity, beryllium-window X-ray tube on extremely fine grained films. Spot welds and

seam welds produce X-ray images of aluminum and its alloys that are entirely different from those of any

other welding technique. Because of the rather large percentage of radiographically dense alloying constitu-

ents that produce informative patterns, some of the high strength aluminum alloys are well suited for spot

weld radiography. The images show positive indications of the following:

a.

Variations in weld nugget shape (oversize, undersize, absence, misshapen, doughnut and crescent

shaped).

b.

Extrusion and expulsion of metal from nugget.

c.

Cracks.

d.

Foreign materials (for example, tip pickup).

e.

Porosity.

f.

Segregation of the alloying elements.

g.

Electrode impressions.

Change 3

6-105