T.O. 33B-1-1

4-53

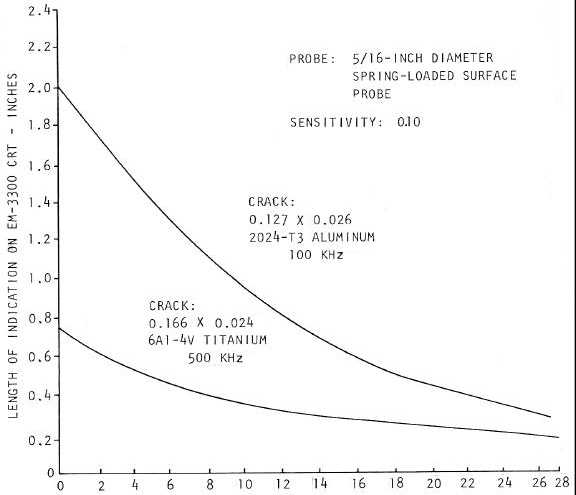

Figure 4-42. Decrease in Crack Response with Increasing Lift-Off.

4.5.4.4

Lift Off Compensation Effects On Sensitivity.

Lift-off must be minimized or compensated for in order to maintain a known level of sensitivity during an eddy current

inspection. A meter type of eddy current instrument requires some form of lift-off adjustment. Otherwise, slight

variations in lift-off would provide strong signals which would completely mask the response from cracks. The

magnitude of crack response is considerably reduced by lift-off compensation. The reduction in sensitivity depends

upon the particular eddy current system in use. Each system must be calibrated for the particular application.

4.5.4.5

Phase Response From Cracks.

Difference in phase between lift-off response and crack response is essential for the detection of cracks in most

applications of eddy current inspection. Depending upon the location of the impedance of the signal on the impedance

diagram, the phase angle between lift-off and crack response can be very small. This makes it very difficult to detect

the difference between lift-off and probe motion from crack indications. Referring to Figure 4-42, as lift-off increases

and/or the frequency decreases, the impedance of the system approaches the air null point, the phase angle between lift-

off and the conductivity line decreases. By maintaining a high fill-factor or low liftoff and operating at a high enough

frequency, a crack indication (loss of conductivity) can be easily distinguished from lift-off signals because of the larger

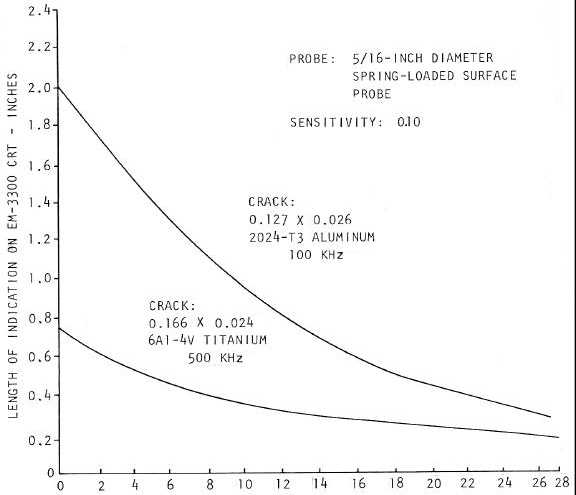

phase angle. These relationships, as seen on an impedance plane analysis eddy current instrument, are shown in Figure

4-43 for aluminum, titanium and steel alloys. As crack depth increases, the phase angle approaches more closely the

phase angle for conductivity changes.