T.O. 33B-1-1

2-57

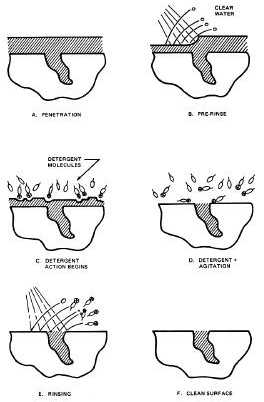

contact the remaining penetrant layer. The action stops when the part is withdrawn from the remover, unlike lipophilic

emulsifiers that become active only after withdrawal and during drainage. Figure 2-20 illustrates hydrophilic remover

action.

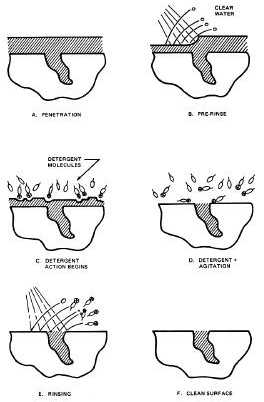

Figure 2-20. Action of the Hydrophilic Process.

2.5.5.4.3

Pre Rinse.

2.5.5.4.3.1 Description.

The clean, preclean, penetrant application and penetrant dwell steps are identical in both the lipophilic and hydrophilic

methods. However, the processes diverge with the pre-rinse step in the hydrophilic method. The part is subjected to a

plain water spray following the penetrant dwell when using the hydrophilic method. The mechanical action of the

water spray removes over 80 percent of the excess surface penetrant, leaving only a very thin uniform layer of surface

penetrant on the part which helps optimize the removal process. It reduces the amount of remover consumed, and in

immersion set-ups, minimizes contamination of remover due to penetrant carry-over. It also reduces remover contact

time since, in general, contact time is about 50 percent less when the pre-rinse step is used. This pre-rinse step cannot

be used in the lipophilic process, as the oil base emulsifier does not tolerate water.

2.5.5.4.3.2 Pre-Rinse Procedure.

The pre-rinse step SHALL be used since it improves the efficiency of the process and minimizes hazardous waste. The

pre-rinse cycle SHALL be a coarse spray of plain water for 30 to 120 seconds, at a pressure as low as practically

possible, not to exceed 40 psig, with a water temperature of 50°F (10°C) to 100°F (38°C). The objective is to reduce

the amount of surface penetrant, while leaving only a thin layer remaining on the part.