T.O. 33B-1-1

2-55

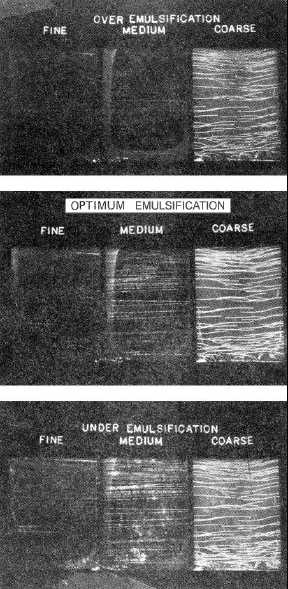

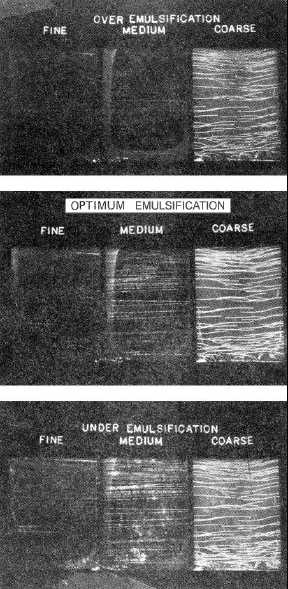

Figure 2-19. Results of Insufficient, Optimum and Excessive Lipophilic Emulsifier Dwell Time.

2.5.5.3.4

Factors Influencing Dwell Time.

2.5.5.3.4.1 Part Surface.

Very smooth polished surfaces retain only a thin layer of penetrant and requires a relatively short emulsifier dwell

period. On the other hand, longer emulsifier dwell times are required for rough surfaces such as sand castings that

retain a thicker layer of penetrant which dictates a longer time for the emulsifier to diffuse to the bottom of the surface

indentations.

2.5.5.3.4.2 Flaw Type.

Tight flaws, with significant depth relative to flaw width, are more tolerant to longer emulsification dwell time than are

wide, shallow flaws. The diffusion rate of even the more active emulsifiers is slowed down when diffusing into

constricted or narrow openings. The diffusion rate on wide, shallow flaws is not slowed, and it is easy to over-emulsify.

Flaw depth is a determining factor for both narrow and wide flaws. Flaws with some depth provide a large reservoir to