development of the first series of thrusters, designated

limitations of the human body in the various flight suits

M1, M2, M3, and M5. Since that time many new and

which have been developed. Table I summarizes the

varied applications for propellant actuated devices have

present limitations outlined in the military specification

been found in the escape system and other weapons

covering the design of propellant actuated devices.

systems for various services.

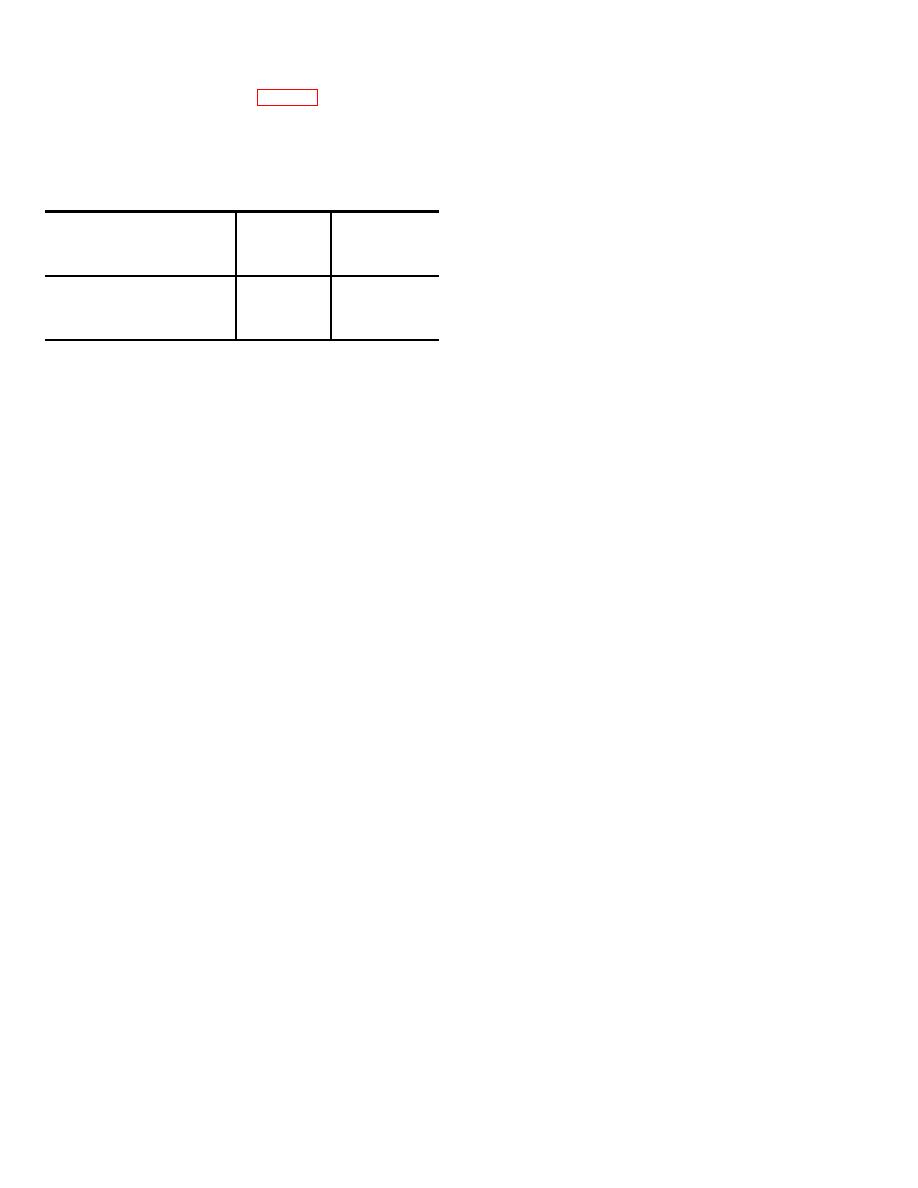

Table I. Physiological Limitations for Personnel

i. Propellant actuated devices are commonly

Ejection

supplied by the Air Force as Government Furnished

Equipment (GFE).

Current development and

Maximum

Maximum

manufacture is accomplished primarily by the Munitions

Direction of ejection

rate of change

Command at Frankford Arsenal. Approximately 175

(g)

of acceleration

propellant actuated devices and cartridges are

(g/sec)

fabricated and over one-half have been standardized

Upward ................................

20

250

and are available off the shelf.

Downward............................

12

125

5. Uses. a. Although propellant actuated devices were

Rearward (seat positioning) .

6

60

developed originally for emergency escape from

aircraft, they have been used for many other short-

duration, high-force applications, such as ejecting radio

f. The first ejection seat catapult was standardized

beacons in the event of a crash, supplying gas pressure

in 1947 and designated the M1 Personnel Catapult. The

to operate hydraulic pumps in missiles, releasing bombs

design and development of the M1 and M2 canopy

or jettisoning stores from aircraft, and ramming

removers followed in quick succession. These early

projectiles into the breech of a howitzer. Propellant

devices were mechanically initiated; i.e., cocked firing

actuated devices are useful in these applications

pins were released by rotating or withdrawing a sear.

because of their reliability, simplicity, light weight, small

The "choke coil," bell-crank rod, and cable-actuated

size, and ability to withstand long periods of storage

system left much to be desired from a reliability,

under extremes of environment without impairment of

simplicity, and maintenance standpoint.

reliability.

g. In 1949, Frankford Arsenal developed a

b. Propellant actuated devices have been

propellant gas pressure source which was designated an

proposed for parachute and cargo separation, reduction

initiator.

Concurrently, the Arsenal redesigned the

of landing shock, landing gear extenders, Gatling gun

existing devices to incorporate a pressure-operated

and missile rotators, and life raft inflators. Applications

firing mechanism. The propellant gas was transmitted

in the form of rotational motors for augmenting or

by hydraulic hose assemblies from the initiators to the

starting standard engines and operation of a varied

firing mechanisms.

family of such devices in space, where weight and bulk

h. With the advent of the B-52 airplane and its

are at a premium, is also practicable. In addition, gas

requirements for multi-crew, multi-functional, integrated

servo mechanisms would eliminate some of the

escape system, it was realized that a new form of

common problems inherent in hydraulic systems by

propellant actuated device (PAD) could furnish thrust to

substitution of gas which is more suitable to applications

position ejection seats, unlock hatches, stow control

involving high temperatures and radiation. All such

columns, etc. In 1951, with the enthusiastic support of

devices are capable of full output on command and may

the airframe contractors and Wright Air Development

be time phased after triggering as desired.

Center, Frankford Arsenal commenced the design and

2