TM 5-3740-218-13&P

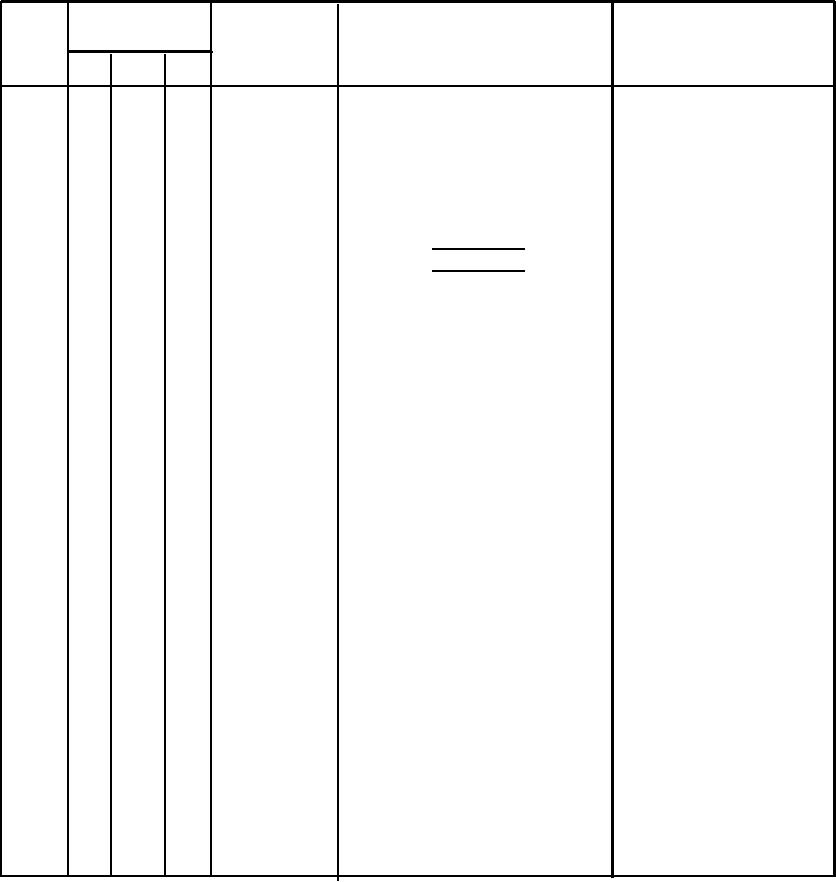

Table 2-4. Operator Level PMCS (Cont)

NOTE: Within designated interval, these checks are to be performed in the order listed.

B-Before

D-During

A-After

EQUIPMENT IS NOT

Item To Be

Procedures

ITEM

INTERVAL

READY/AVAILABLE IF:

Inspected

NO.

B

D

A

Hydraulic

Check for proper hookup to pump

Leaks exceed Class II,

Lines

and primary manifold. Check for

or lines installed

leaks at manifold and rotary

incorrectly.

atomizers.

Rotary

Check for secure mounting.

Mounting is loose.

Atomizers

WARNING

Operator should be aware

that foreign objects in

slinger can cause injury

when system is activated.

13

SD System

Check all L-clamps for tightness.

Missing L-clamps

Chutes

Check for proper attachment of

cause leaks, or chute

hydraulic lines. Check chute

gates malfunction.

gates for smooth operation and

tight closure.

Empty

Check empty sensor connection

Light on hand control

Sensor

and operation.

unit inoperative.

14

SD System

Check tightness of attachment

Hardware missing or

Slinger/

hardware. Check for proper

slinger malfunctions.

Hopper

attachment of hydraulic lines.

Assembly

Check for proper activation by

hand control. Check for foreign

objects in slinger.

15

Liquid

Flush entire system including

All assemblies not

System

bucket, crosstube and pump

properly cleaned.

assembly, booms, nozzles, liquid

pesticide lines (ULV), and rotary

atomizers using appropriate

solvent.

2-13