TM 5-3740-218-13&P

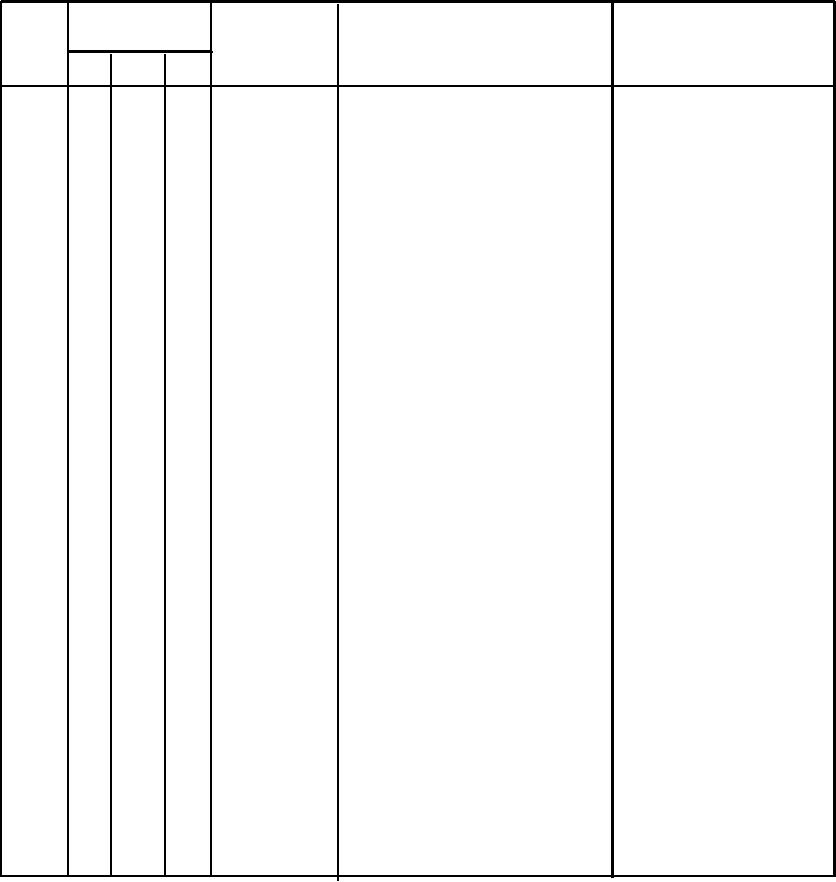

Table 2-4. Operator Level PMCS (Cont)

NOTE: Within designated interval, these checks are to be performed in the order listed.

B-Before

D-During

A-After

EQUIPMENT IS NOT

Item To Be

Procedures

ITEM

INTERVAL

READY/AVAILABLE IF:

Inspected

NO.

B

D

A

Strainer

Check for cleanliness; clean with

Strainer plugged.

water or appropriate solvent.

Pump and

Fails to operate.

Crosstube

correct location and secureness of

Spray

hookup. Check operation with

System

hand control.

Control

Valve

Level

Check connections. Check for

Fails to operate.

Sensors

proper operation (indicator lights

when bucket is empty).

11

LV Booms

Check for proper assembly. Make

Cannot be secured.

and Struts

sure all quick-release pins are

secured.

Boom

Check for missing or compressed

Missing, or leaks

Kamlock

gaskets. Check for leaks.

exceed Class II.

Gaskets

Spray

Check for leaks using water.

Leaks exceed Class II,

Nozzles

Check for correct/uniform spray

or spray produces

pattern. If threads are stripped

excessively large

or body cracked, refer to unit

droplets.

maintenance.

12

ULV Boom

Check for secure attachment,

Not secured, or broken.

broken, or missing parts.

Quick-release pins should be fully

engaged.

Boom

Check for missing or compressed

Missing, or leaks

Kamlock

gaskets. Check for leaks.

exceed Class II.

Gaskets

Liquid

Check for leaks at all connections.

Leaks exceed Class II.

Pesticide

Lines

Nozzles

Check for leaks using water.

Leaks exceed Class II.

2-12