TM 5-6635-386-12&P

Seating area requirements for the transmission mode

comprise only a 2 x 6-inches wide surface under the GM

tube, thus the tester can be used on very difficult

surfaces where a backscatter tester would be impossible

to use.

Transmission surface roughness error is approximately

1/10th that of the backscatter errors.

1-18. DRILL TRANSMISSION HOLE

The transmission hole must be vertical to the smoothed

surface and must not be damaged in the process of

drilling and retraction of the drill.

Place the Cast Guideplate on the surface and use the

guide to support the drill pin. Hammer the drill pin into

the ground, tap it lightly to loosen it, twist it to further

loosen it, and pull it out of the ground.

WARNING

Do not use the cast guideplate as a retraction

device. It will damage the top of the guide hole.

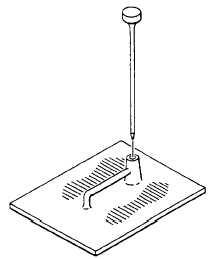

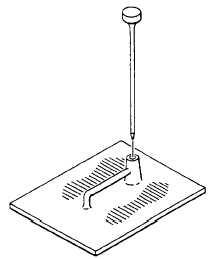

Figure 1-6. Transmission Hole

NOTE

During drilling and retraction, the operator’s weight on the

guideplate confines the soil to prevent eruption or

puffing.

The operator’s weight on the plate confines the soil in

drilling and in retraction to produce a neat, undamaged

hole for the readings.

On heavily compacted material above 95%, cracks may

appear in the soil. These will not affect the readings if

the tester is placed so no crack extends from the source

directly back to the detector tubes.

If the drill pin "walks away" as a result of striking a rock in

the soil, try another location. If repeated tries cannot

produce a satisfactory hole, then the test should be

aborted.

1-19. SEATING THE TESTER IN TRANSMISSION

From a radiation exposure standpoint, it is undesirable to

have to spend a great deal of time "playing" with the

tester in seating it. Locating the hole for insertion of the

source rod in transmission is frequently a problem and

CPN has made this easy for the operator.

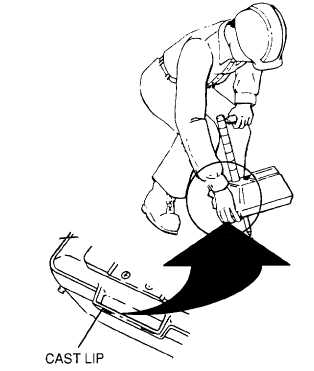

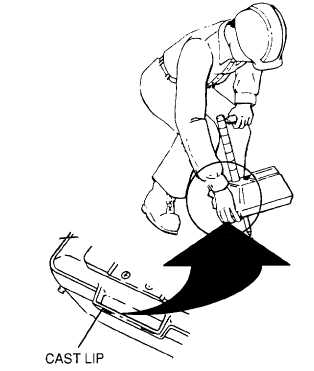

Figure 1-7. Positioning Source in Prepared Hole

A small cast lip (Fig. 1-7) is on the front of the bottom

casting to provide for insertion ease.

1-15