TM 5-3740-214-14

Table 5-3. Direct and General Support Maintenance Troubleshooting (Continued)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

ENGINE BACKFIRES (Continued)

d.

Set the choke wide open. Remove the air cleaner if necessary.

e.

Crank the engine by hand counterclockwise (left: opposite to normal rotation).

f.

Take eight to ter compression readings.

(1)

The first few turns of the engine, the compression may be as low as 30 psi.

After the seventh turn, the compression should be 90 psi.

(2)

If the compression is less than 90 psi, replace the engine.

12.

NOZZLE PRESSURE BELOW 90 PSI

Step 1.

Turn the engine ON and listen to the compressor.

a.

If it runs smoothly, go to Step 2.

b.

If the compressor makes grinding, rubbing or rattling noises, go to Step 1c.

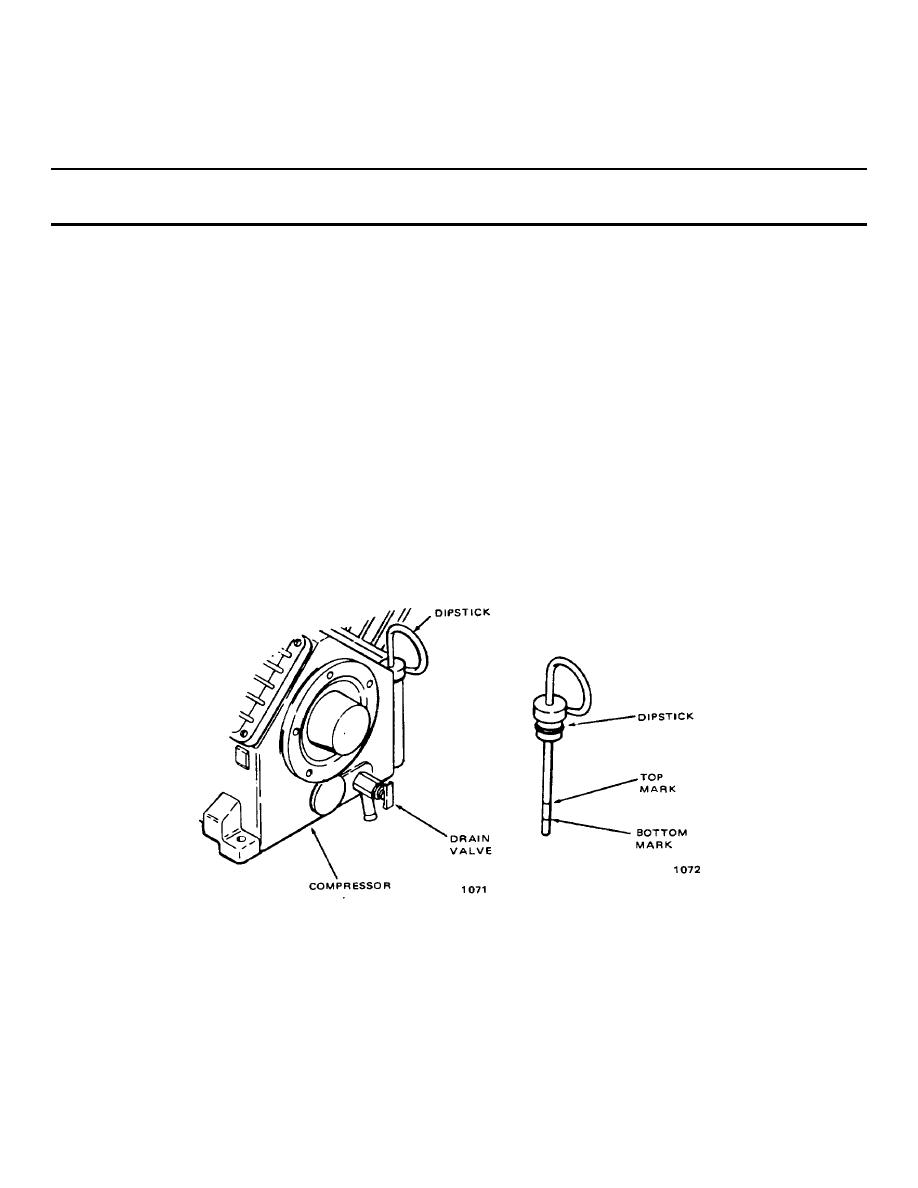

Figure 5-190. Compressor Dipstick

5-171