TM 5-3740-214-14

Table 5-3. Direct and General Support Maintenance Troubleshooting (Continued)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

ENGINE KNOCKS (Continued)

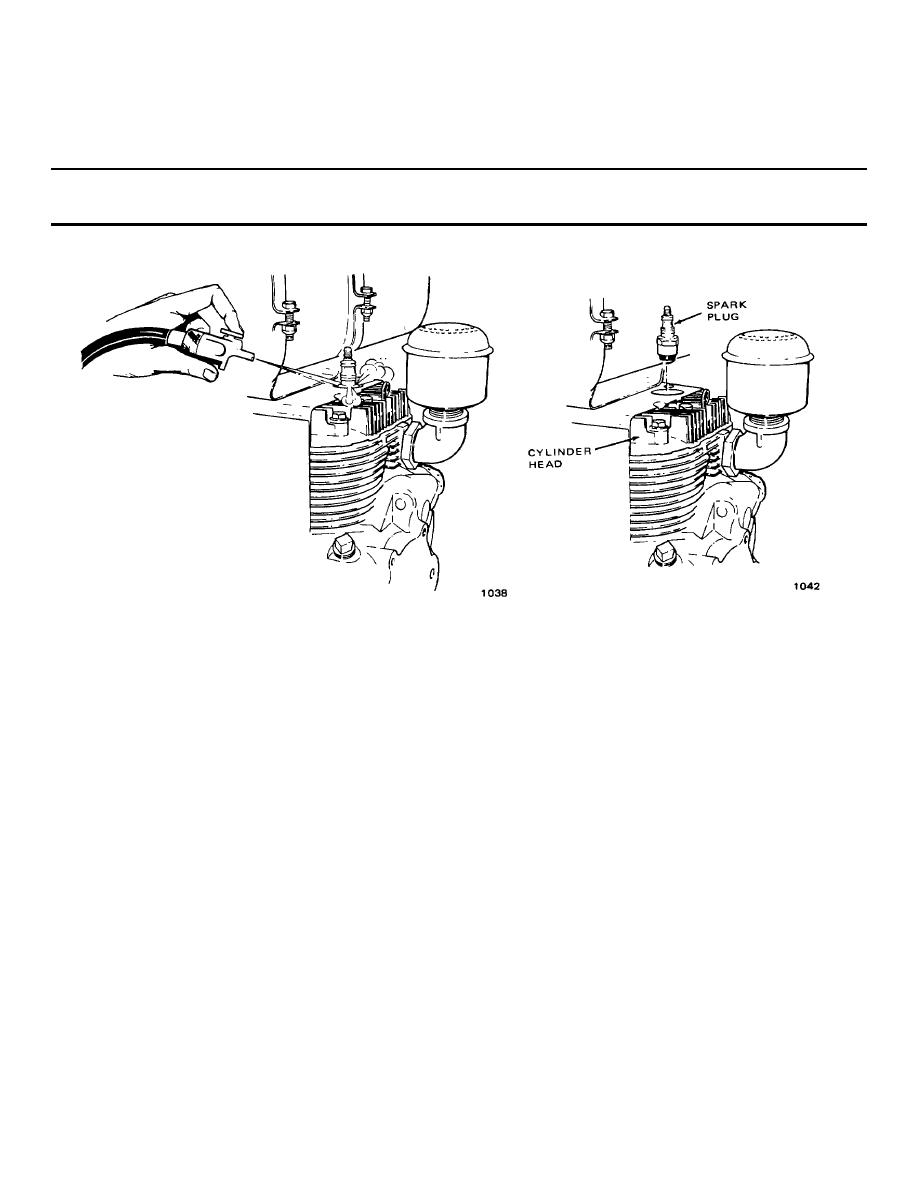

Figure 5-170. Spark Plug Cleaning

CAUTION

BE CAREFUL when removing the spark plug. Too much force can break the insulator.

(1)

Loosen the spark plug a few turns.

(2)

Blow out the spark plug well with high pressure air. This will clean out any dirt or debris that can

fall into the cylinder.

(3)

Remove the spark plug by hand.

c.

Place a compression gage in the spark plug hole. Make sure it seals well.

d.

Set the choke wide open. Remove the air cleaner if necessary.

e.

Crank the engine by hand counterclockwise (left: opposite to normal rotation).

f.

Take eight to ten compression readings.

(1)

The first few turns of the engine, the compression may be as low as 30 psi. After the seventh

turn, the compression should be 90-100 psi.

(2)

If the compression is less than 90 psi, replace the engine.

5-155