TM 53740-214-14

Table 5-3. Direct and General Support Maintenance Troubleshooting (Continued)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

ENGINE OPERATES ERRATICALLY (Continued)

CAUTION

DO NOT use hard metal objects or tools to clean the inlet port. Use

something soft like a toothpick and flush the port with alcohol or acetone.

(4)

Unplug the inlet port if necessary.

(5)

If the choke is worn or damaged, replace the whole carburetor and go to Step 8b.

(6)

Unplug the inlet port if necessary and go to Step 8e.

e.

Assemble the carburetor.

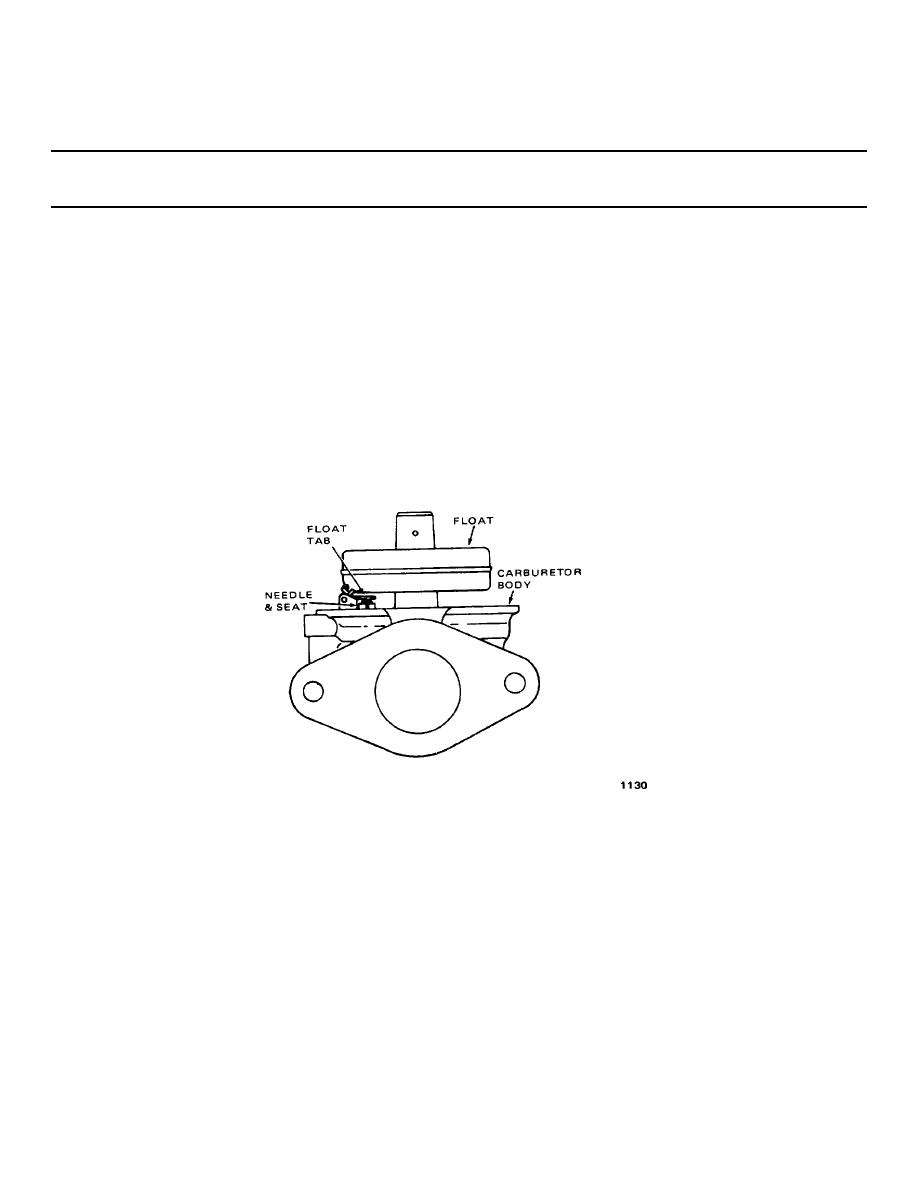

Figure 5-164. Carburetor Float Adjustment

(1)

Install the seat needle float and pin.

(2)

Set the float level. Turn the carburetor upside down and let the float rest on the needle. The

clearance between the machined surface of the carburetor and the free end of the float should

be 0.17 inches 0.03 inches (4.37 mm 0.76 mm).

(3)

Adjust the clearance by bending the float tab with a screwdriver if necessary.

(4)

Install a new baffle gasket, a new bowl gasket, the fuel bowl and a bowl screw. Make sure the

bowl gasket seats well.

5-149