TM 5-3740-214-14

Table 5-3. Direct and General Support Maintenance Troubleshooting (Continued)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

ENGINE OPERATES ERRATICALLY (Continued)

(4)

Hold the end of the spark plug about 3/16 inch (4.76 mm) from a grounded part of the engine.

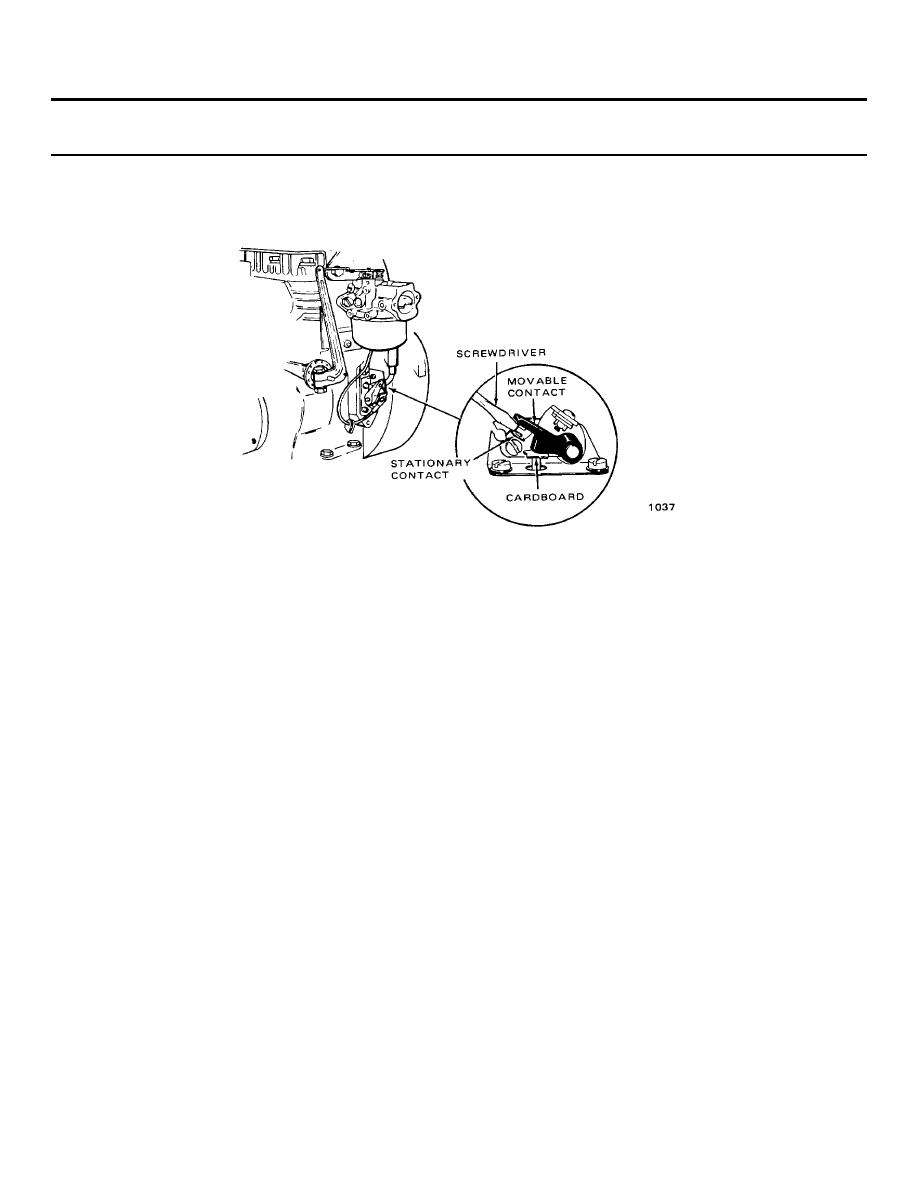

Figure 5-153. Breaker Points

(5)

Hold a screwdriver point across the open breaker points.

(6)

Remove the screwdriver from the breaker points.

(7)

If a bright blue spark jumps between the wire and the engine, the coil is ok. Go to Step 5.

(8)

If there is no spark or the spark is weak and yellow, the coil is weak. Replace it and go to Step

4e, if the condenser and the points check ok.

c.

Coil Test I. Check the primary coil winding. Use a volt-ohmmeter.

(1)

Remove the breaker point cover and jam a piece of cardboard between the breaker points.

(2)

Turn the ignition switch ON.

(3)

Connect the negative (-) meter lead to a grounded part of the engine.

(4)

Connect positive (+) meter lead to the battery (+) side of the coil. If the meter reads 11.5 to 12

volts, there is current to the coil. Go to Step 4c(5). If the meter reads 11.5 volts or less, there is

poor current to the coil. Go to Step 4d.

(5)

Coil Test II. Connect the positive (+) lead to the breaker points (-) side of the coil. If the meter

reads 11.5 to 12 volts, the coil is ok. Go to Step 8. If the meter reads 11.5 volts or less, the coil

is bad. Replace it and go to Step 4e, if the points and condenser check ok.

5-139