TM 10-8415-210-13&P

5-13. M2A1 TAP BOOTS

This task covers:

a.

Inspect M2A1 TAP Boots

b.

Leak Testing M2A1 TAP Boots

INITIAL SETUP

Tools:

Air Leakage Tester, Q79A1 (Appendix B, Section III, Item 1)

Tank, Electrically Heated (Appendix B, Section III, Item 7)

Materials/Parts:

Ink Pad, Rubber Stamp (Appendix F, Item 11)

Ink, Stencil (Appendix F, Item 12)

Chalk, White (Appendix F, Item 1)

Stencil Roller (Appendix F, Item 18)

Equipment Condition:

Boots must be clean and decontaminated.

a.

Inspect. Inspect boot in accordance with procedures outlined in Table 2-1. Use Equipment Inspection and

Maintenance Worksheet DA Form 2404 to record all defects found. If inspection reveals a condition that renders a boot

unserviceable, turn-in IAW local SOP.

b.

Test.

NOTE

Pause at each observation point no less than 10 seconds.

Visible bubbling at any point during the test is not acceptable,

excluding bubbles caused by surface trapped air.

(1)

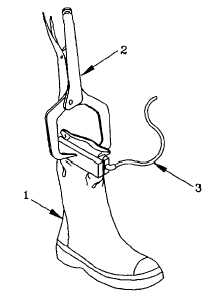

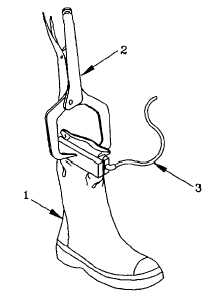

Seal the top of the boot (1) with an air pressure clamp (2), by placing the boot material flat between the

clamp plates.

5-16