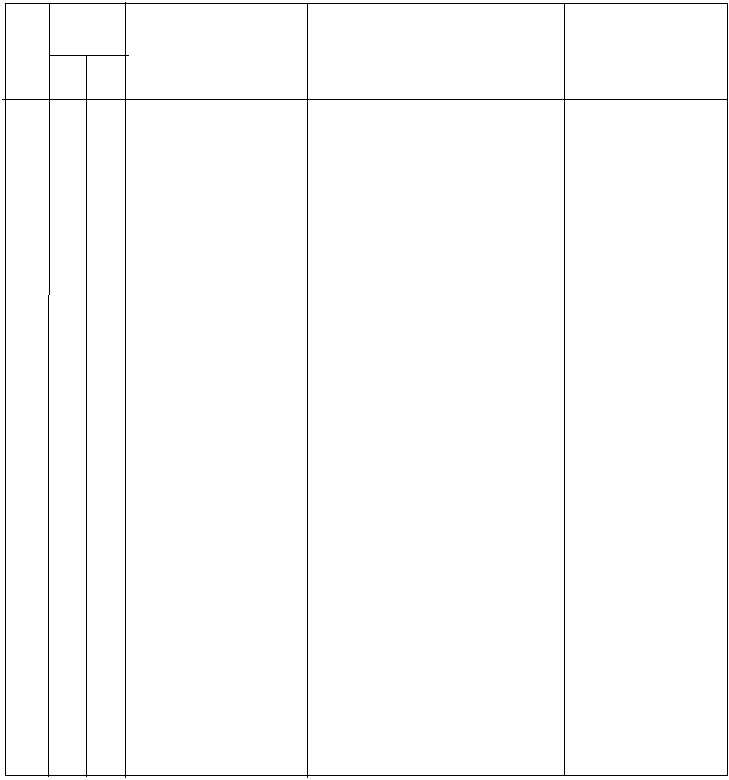

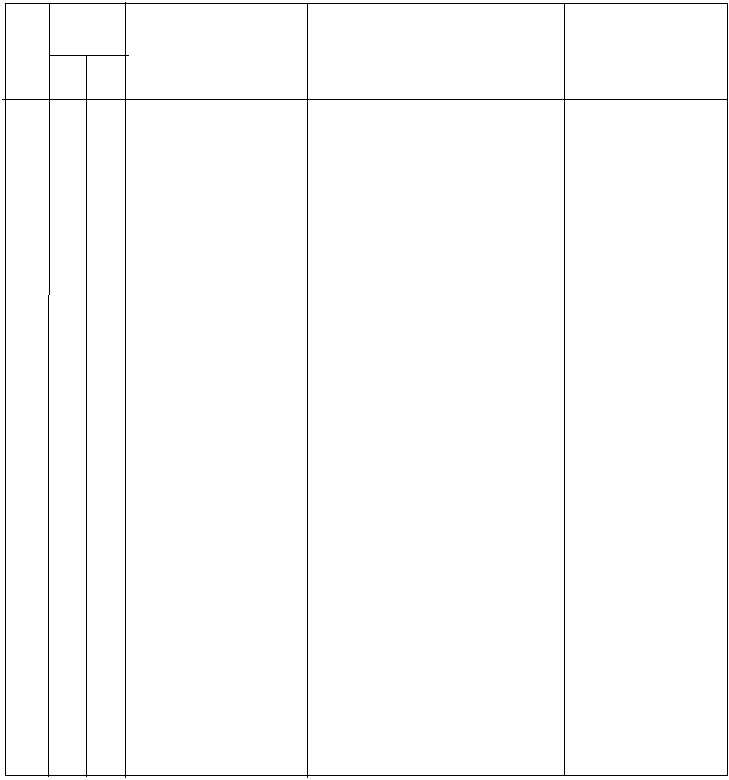

TM 10-8415-208-12

Table 3-2. Unit Preventive Maintenance Checks and Services for the STEPO-I(Cont)

A - After Operation

Q - Quarterly

INTERVAL

Item

Item To Be

Procedures

Equipment Is

No.

Inspected

Check For And Have Repaired

Not Ready/

A

Q

Or Adjusted As Necessary

Available If:

CAUTION

Equipment corrosion hazard. Remove

the battery from the EBA battery box

when the unit is not in use. Failure to

remove the battery may cause

equipment damage from corrosion and

require replacement of the EBA.

33

Battery

Ensure "D" size battery is available.

Battery not available.

34

Remove battery from battery box.

Battery is installed.

35

Cylinder

Check the pressure gauge to

Cylinder is not

ensure the cylinder is charged

charged approxi-

to approximately 2500 PSIG.

mately 2500 PSIG

or date of last

hydrostatic test is

not current.

NOTE

The hydrostatic test date is stamped on

the cylinder near the neck.

36

Check hydrostatic test date

Test date is over 5

years old.

37

Cushion Cover

Ensure cushion cover is

Cushion cover not

available.

available.

38

Check for cuts, rips, tears,

Damage is found.

missing or broken snaps.

NOTE

The EBA shall be tested before initial

wear, after each use, monthly, after

specified maintenance and when

damage is suspected due to a visual

inspection or poor performance.

39

Leak Test

Perform leak test (See paragraph

Fails leak test.

3-9.3.3).

40

Static Pressure

Perform static pressure test.

Fails the pressure

Test

(See paragraph 3-9.3.1 )

test.

41

Air Flow

Perform air flow performance

Fails the test.

Performance Test

test. (See paragraph 3-9.3.2.)

NOTE

PMCS steps 42 through 67 pertain to

the rebreather system mode.

Change 2 3-139