TM 10-5410-228-24

Section III. DIRECT SUPPORT MAINTENANCE PROCEDURES

a. This section provides procedures for the replacement and repair of major components and assemblies

which fall within the scope of direct support maintenance.

b. Remove/disassemble only to the extent necessary to remove or replace defective

assemblies/components. Use standard maintenance shop practices/procedures.

EXPANDED CAPACITY VEHICLE (ECV).

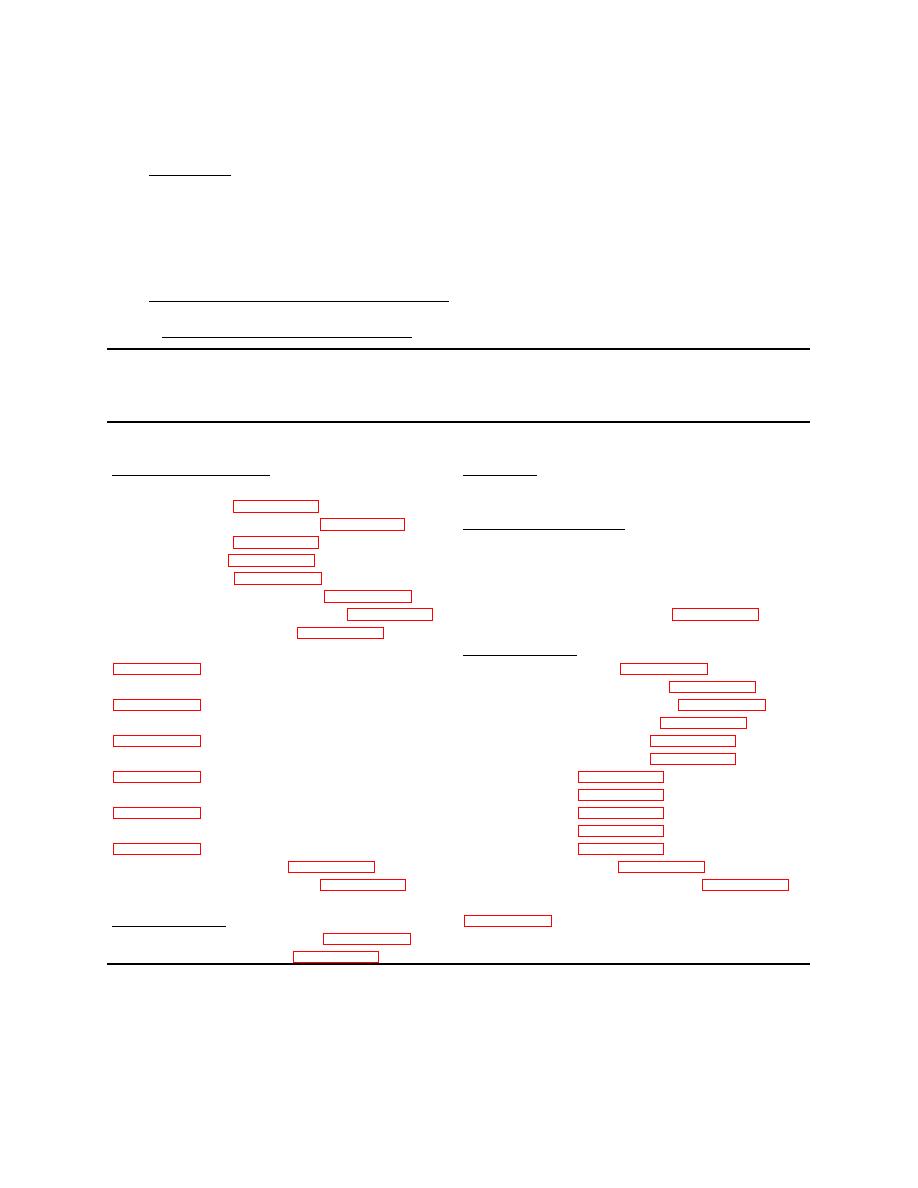

This task covers:

a. Removal

c. Assembly

b. Disassembly

d. Installation

e. Prime Hydraulic Pump

INITIAL SETUP

Tools/Test Equipment:

Reference:

Shop Equipment, Automotive Maintenance and

TM 10-5411-224-14

Repair (Item 38, Appendix B)

Drill, Electric, 1/2 in. (Item 6, Appendix B)

Equipment Conditions:

ECV off, system power off, power panel and

Drill Set (Item 5, Appendix B)

ECV tagged.

Gloves (Item 16, Appendix B)

ECV parking brake set.

Goggles (Item 17, Appendix B)

Power cable disconnected.

Riveter, Blind, Hand (Item 34, Appendix B)

Hydraulic system drained (see para 2.14.3).

Jack, Hydraulic, 12 Ton (Item 20, Appendix B)

Light, Extension (Item 24, Appendix B)

Materials/Parts: (Cont.)

11/16 Inch Crowfoot Wrench (Item 53,

Wiping Rags (Item 39, Appendix C)

Grease, Automotive (Item 27, Appendix C)

13/16 Inch Crowfoot Wrench (Item 54,

Sixteen Lockwashers (Item 18, Appendix E)

Four Lockwashers (Item 20, Appendix E)

15/16 Inch Crowfoot Wrench (Item 55,

Six Lockwashers (Item 21, Appendix E)

Six Lockwashers (Item 22, Appendix E)

1-1/8 Inch Crowfoot Wrench (Item 57,

O-ring (Item 61, Appendix E)

O-ring (Item 63, Appendix E)

1-3/8 Inch Crowfoot Wrench (Item 60,

O-ring (Item 50, Appendix E)

O-ring (Item 57, Appendix E)

1-7/8 Inch Crowfoot Wrench (Item 63,

O-ring (Item 53, Appendix E)

Two O-rings (Item 54, Appendix E)

Torque Wrench (Item 66, Appendix B)

Forty-three Blind Rivets (Item 80, Appendix E)

Collar Set, Drill Stop (Item 2, Appendix B)

Twenty-four Self-locking Nuts (Item 42,

Materials/Parts:

Antiseize Compound (Item 13, Appendix C)

Hydraulic Fluid (Item 24, Appendix C)

NOTE

Remove/disassemble only to the extent necessary to remove or replace defective

assemblies/components. Use standard maintenance shop practices/procedures.