T.O. 33B-1-1

6-80

e. The film should be flat and taut with the punched number (if any) at the bottom of the hanger. If it is

not, repeat the procedure.

6.7.12.4

Manual Processing.

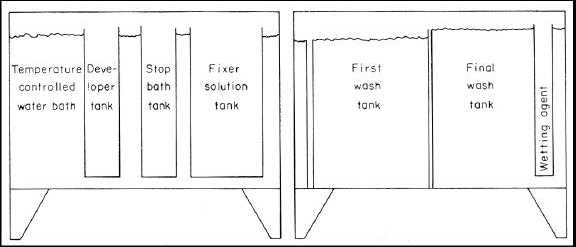

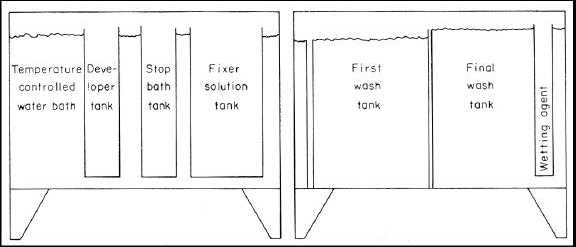

Suggested arrangement of manual processing tanks is shown in Figure 6-38. The chemicals should be arranged as

shown in the sketch in sequential steps of the process and traversing from left to right. This arrangement is used with

the assumption that most people are right-handed.

Figure 6-38. Suggested Arrangement of Manual Film Processing Tank.

6.7.13

Preliminary checks.

a. Be sure all films are placed on hangers properly.

b. Check the temperature of all processing solutions using a bimetallic thermometer. Refer to Table 6-16.

c. Agitate the developing chemicals and make sure they are at the proper level; replenish if necessary.

d. Be sure wash water flow is adequate. Refer to Table 6-17.

6.7.14

Developing Procedure. (See Figure 6-39)

CAUTION

Do not allow films to remain out of solutions for extended periods of time since this

will cause uneven development.

NOTE

Drain the films and hangers for several seconds between operations to prevent

carryover of chemicals from one tank to another.