T.O. 33B-1-1

6-63

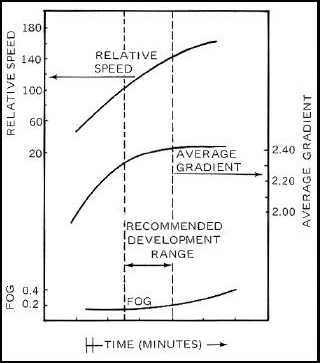

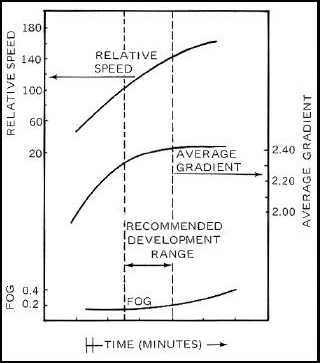

Figure 6-30. Effect of Development Time upon Film Speed, Contrast and Fogging.

6.7.3

Radiographic Sensitivity.

6.7.3.1

Penetrameters.

CAUTION

Use the IQI specified in the technique. Consult with the appropriate ALC NDT

Level III for instructions if the IQI identified in the technique is not available. IQI’s

are not generally required for inspection for the presence of debris, for proper

assembly of components, for dissimilar material inspection, for honeycomb

structures, or for the presence or absence of material.

There is a need to be able to qualitatively define how sensitive a radiographic image is. The devices that achieve this

aim are known as penetrameters. Another description is image quality indicators (IQI). By whatever name, they

provide an indication of what the film reader can be expected to see in the actual part being inspected. A wide range of

penetrameters is specified for use by various industries. ASTM plaque-like type penetrameters (or as now more

commonly called image quality indicators) are described in Ref. 13. Wire penetrameters, particularly useful for weld

inspection, are described in Ref. 14. In their current form, penetrameters are a small plaque, fabricated of the same

material as that being radiographed. The thickness of the penetrameter is a known percent of the test object thickness.

Holes in the penetrameter are of diameters 1T, 2T, and 4T when T equals penetrameter thickness. Thickness

visualization of these holes can be related to the sensitivity of the radiographic image. A typical penetrameter is shown

in Figure 6-31.