T.O. 33B-1-1

6-62

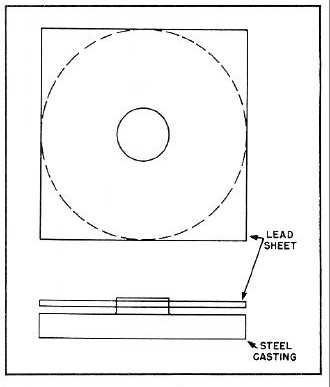

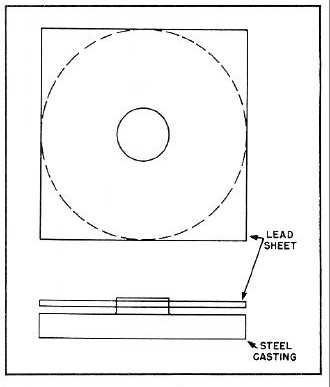

Figure 6-29. Masking to Avoid Scatter.

6.7.2.11.2

The control of scatter requires common sense and ingenuity. A concrete, wood or composition floor will generate

enough back-scattered radiation to fog a film. Film holders should always be laid on or backed with a sheet of 1/8-inch

lead. The backing should be as large as the primary radiation field. This thickness of lead is enough for radiation

generated up to 300 kVp, except where fluorescent screens are in use, 1/4 inch should be used. The Potter-Bucky Grid

is a device especially constructed to absorb object scatter radiation. Effectively, this grid is made somewhat like a

Venetian window shade; it consists of strips of material comparatively transparent to radiation and strips of lead. The

strips of lead absorb object scatter radiation at angles other than the direct beam. To prevent the lead strips from being

revealed in the image, the grid is moved during exposure so the image of the lead strips is actually distributed over the

entire image but does not show detail. These Potter-Bucky Grids are usually used in industry for radiography of low

atomic materials where scatter is a problem of considerable proportions, especially in medicine.

6.7.2.12

Effect Of Processing.

Processing variables, especially development time, also affects density and film contrast through their effect upon the

slope of the characteristic curve. Tests with a typical industrial film showed that as development time was reduced, the

effect was to produce a family of characteristic curves displaced to the right. That is, the log relative exposure needed

to produce a standard density increased as development time decreased. There were other effects too. Figure 6-30

shows that an optimum development time maximized the slope of the characteristic curve (and thus film contrast) at

only slight cost in fogging.