T.O. 33B-1-1

6-48

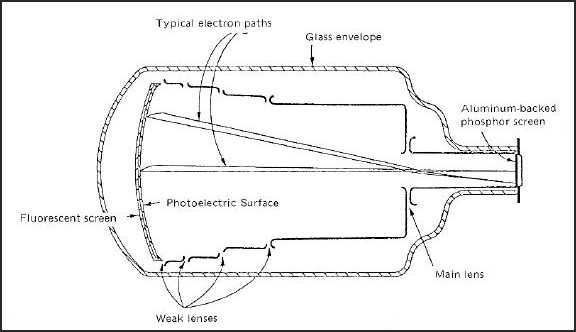

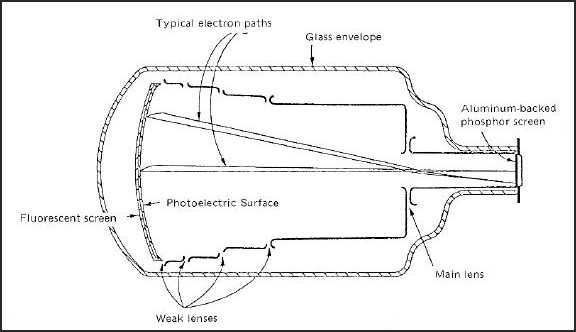

Figure 6-20. Typical Image Intensifier Tube.

6.6.3.4

X-Ray Vidicon.

The X-ray vidicon system consists of a specially designed television camera that is directly sensitive to X-rays. It has a

specially coated face that is capable of imaging X-radiation, because, its electrical resistance changes with radiation, a

phenomenon called photoconductivity. This small area coating provides very fine resolution. The results of this type of

inspection are displayed on a television monitor. The sensitive area of the television vidicon tube is generally very

small, on the order of 3/8 by l/2 inch. When this small area is viewed on a 17-inch television monitor, a magnification

of 30 times results, thus very high detail resolution is accomplished. These systems are used primarily for the

inspection of very fine detail, such as in the inspection of microelectronic circuits. This system is capable of resolving

wires as small as 0.001 inch in diameter.

6.6.3.5

Stereoradioscopy.

Stereo imaging can be done in real-time, using microfocus X-ray sources, geometric magnification and radioscopic

systems (see paragraph 6.6.3.1). The stereo pair images can be obtained using only minimal movement of the

microfocus X-ray source when geometric magnification is used. This stereo pair imaging can be done by magnetic

movement of the X-ray tube electron beam. The two stereo views, obtained at TV field rates (1/60 second), can be

combined electronically into a stereo pair image for 30-frames/second viewing. An observer, wearing special

polarizing glass and looking at the television stereo image through a 1/60 second changing polarizing filter, will see a

stereo, radioscopic image.

6.6.3.6

Photoradiography.

Photo radiography is a combination of radioscopy and photography. In this method, the image of a fluoroscopic or

image intensifier output screen is photographed by a conventional camera on small or miniature-type film rather than

by direct contact. This method has the advantage over fluoroscopy in that the film has the property to integrate and

react to the total light emitted by the screen during the time of exposure, whereas the integration time of the eye is

relatively short. Furthermore, the resultant film can be viewed with transmitted light and the photographic process can

be used to enhance the contrast of the fluorescent image. This method has been used to limited extent for the

examination of propellant grains, die and precision castings, and similar parts and assemblies when a large number of

parts of the same configuration and size are inspected. Airframes have been inspected for component shift and material

changes by using photoradiography. The system has limitations since all fluorescent screens commonly used are

grainy. In addition, there is loss of definition through the lens of the camera. The main advantage of the system is the