T.O. 33B-1-1

5-42

5.3.3.1.2

Limitations.

5.3.3.1.2.1

Dead Zone.

The dead zone interferes with contact inspection of near-surface regions of parts. When required, the coverage of a

straight beam inspection in near-surface regions can be extended by several different methods, such as the following:

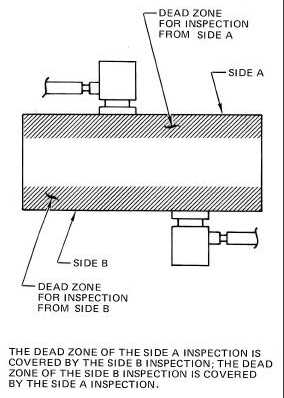

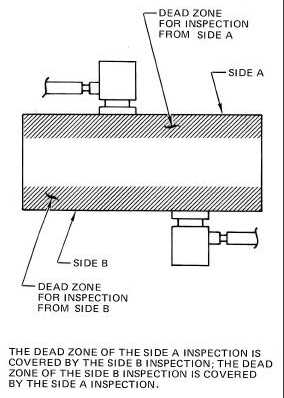

a. Inspect the part from opposite sides. The dead zone, which is not inspected from the first side, is

covered when inspecting from the second side (see Figure 5-45).

b. Use a dual search unit (see paragraph 5.2.2.4).

c. Use a delay line contact search unit (see paragraph 5.2.2.6).

d. Use an immersion inspection method.

Figure 5-45. Inspection of Test Part Opposite Sides to Provide Coverage of Dead Zone Areas.

5.3.3.1.2.2

High Attenuation.

In some cases, when inspecting thick sections, the sound energy in the part drops below useable levels. If this happens,

inspecting from opposite sides can help, since only half the section thickness needs to be covered in a single inspection.

If inspecting from two sides, the zones must overlap by a minimum of 1/2". The limitation of high attenuation may

also be alleviated by using the through-transmission technique.

5.3.3.1.3

Through-Transmission Technique.

Most straight beam methods are applied using the pulse-echo technique in which the transmitting and receiving search

unit or units are placed on the same surface. Certain applications use the through-transmission method in which the

transmitting search unit is placed on one surface and the receiving search unit is placed on the opposite surface. In the

through-transmission method, discontinuities block the passage of sound. This results in a reduction of the received