T.O. 33B-1-1

3-82

demagnetization is desired the coil is then placed in position with the part still clamped in the heads. The same general

procedure is followed, except that the demagnetizing current passes through the coil instead of the part.

3.6.6.2

Mobile.

Mobile equipment used for magnetization can also be used for demagnetization. Demagnetization is performed by

selecting a current output equal to or greater than the one that was used when magnetizing the part. Cables are either

formed into a coil of three or four turns, or wrapped around the part three or four times. The cables are then connected

to the output terminals. On units without a demagnetization cycle, initiate the magnetizing cycle and pass the part

through the coil or pass the coil over the part, leaving the current on until the coil and part are well separated

(approximately 4 to 5 feet). On units incorporating a demagnetization capability, place the part in the coil, and initiate

the demagnetization cycle that starts the automatic step-down of the applied current.

3.6.6.3

Portable.

Portable equipment, other than hand probes or yokes will usually supply both alternating current and half-wave direct

current. Demagnetization with this equipment and cables is done using alternating current as follows:

a. Make a coil of three or four loops of cable. Adjust the alternating current output to a higher level than

was used in magnetizing the part. Place the coil around the part and turn on the current. Then

withdraw the coil four or five feet from the part and turn off the current.

b. Alternatively, make a coil of three of four loops of cable around the part. Adjust the alternating current

output to a higher level than was used in magnetizing the part. Turn on the current. Then withdraw

the part from the coil for four or five feet along the centerline of the coil and turn off the current.

3.6.6.4

Hand Probe or Yoke.

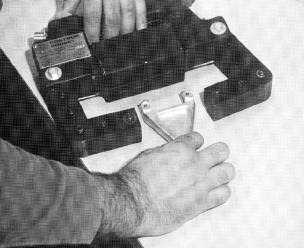

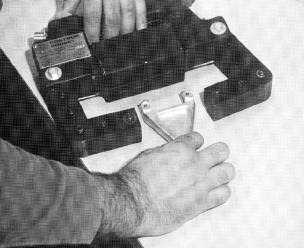

Hand probes or yokes, either AC or DC; provide a portable means for demagnetizing when other methods are

impractical. In some cases they are more effective than coil-type demagnetizers are, because the field of the probe or

yoke can be concentrated into a relatively small area. For probes with adjustable legs the space between the poles

should be such that parts to be demagnetized will pass between them as close as possible. With AC flowing in the coil

of the probe, parts are passed between the poles and withdrawn (as shown in Figure 3-37). On large parts, the probe is

placed on the part and is moved around as it is slowly withdrawn. This method of demagnetizing is very effective.

When the probe incorporates a DC magnetization capability, it can be used for DC demagnetization as well.

Figure 3-37. Non-Contact Demagnetization