T.O. 33B-1-1

3-77

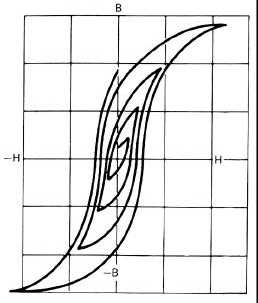

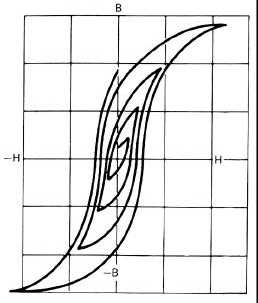

a. One of the simpler methods subjects the magnetized part to a magnetizing force that continually

reverses its direction. At the same time, this force is gradually decreased in strength. As the decreasing

magnetizing force is applied, first in one direction and then the opposite direction, the magnetization of

the part is decreased. This decreasing magnetization is accomplished by smaller and smaller hysteresis

loops created by the application of decreasing current as shown in Figure 3-35. The smaller the

hysteresis loop produced the more demagnetization that has been accomplished.

Figure 3-35. Hysteresis Loops Produced During Demagnetization

b. For all practical purposes the only way to completely demagnetize a part is to heat it to its Curie point

or above.

c. Under normal conditions, a part is considered to be satisfactorily demagnetized if, when checked with a

field indicator, the magnetic field is at or below 3 units on a gaussmeter or 2 units on a field indicator.

3.6.4

Requirements.

Aircraft ferromagnetic parts require demagnetization principally to prevent magnetic flux from affecting

instrumentation. There are several additional reasons supporting the requirement for demagnetization.

3.6.4.1

Situations Requiring Demagnetization.

Demagnetization is required when the residual field in a part:

a. May interfere with subsequent machining operations by causing chips to adhere to the surface of the

part or the tip of a tool that may become magnetized from contact with the magnetized part. Such chips

can interfere with smooth cutting by the tool, adversely affecting both part surface finish and tool life.

b. May interfere with electric arc or electron beam welding operations. Residual magnetic fields may

deflect the arc or electron beam away from the point at which it should be applied.

c. May interfere with the functioning of the part itself after it is placed into service. Magnetized tools,

such as milling cutters, hobs, etc., will hold chips and cause rough surfaces, and may even be broken by

adherent chips at the cutting edge.

d. Might cause trouble on moving parts, especially those running in oil, by holding particles of metal or

magnetic testing particles - for instance, on balls or races of ball bearings, or on gear teeth.