T.O. 33B-1-1

2-84

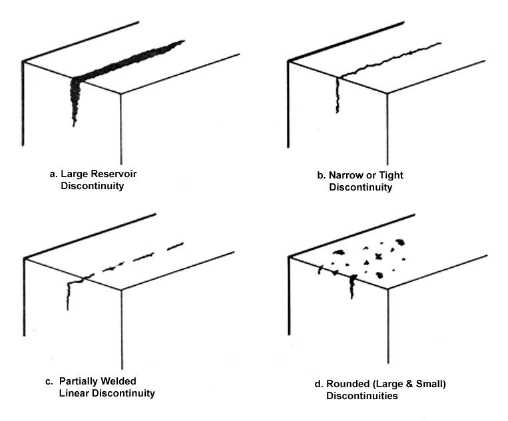

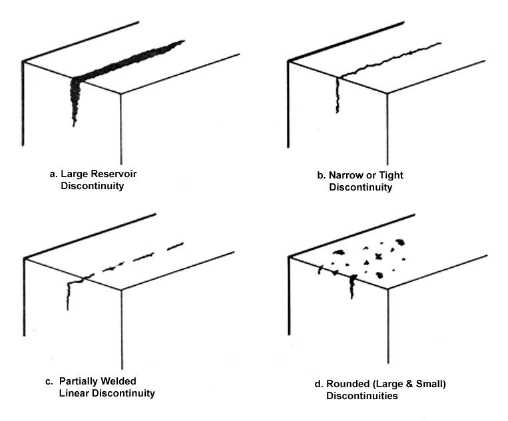

breaks the surface for its entire length or a partially filled seam will also produce an intermittent linear indication as

shown in Figure 2-32c.

2.7.6.2.1.3 Round or Dot Indications.

Rounded indications are characterized as having a length and width of approximately equal dimensions. Porosity or

relatively small areas of unsoundness in metal components usually form rounded indications. However, the actual

surface opening may be irregular in shape. Deep discontinuities, such as weld crater cracks, may appear rounded due

to the large volume of entrapped penetrant. Figure 2-32d illustrates the appearance of large and small rounded

indications.

Figure 2-32. Typical Penetrant Indications.

2.7.6.2.2

Manufacturing Discontinuities.

Many discontinuities result from the manufacturing and repair processes. These will probably be detected each time

the part is reinspected. The NDI inspector must, therefore, be familiar with their appearance and cause, in order to

make valid interpretations of inspection results. Some of the common types of manufacturing discontinuities are

described and illustrated in the following paragraphs.

2.7.6.2.2.1 Porosity.

Porosity is common to all cast parts, particularly aluminum and magnesium. Porosity occurs when gases are entrapped

in the molten metal during pouring and solidification and may also occur during welding. It does not always break the

surface, and internal porosity is not detected by penetrant inspection. Porosity can be very small and distributed

throughout the material, in which case it is called microporosity. Microporosity may or may not cause a penetrant

indication. When it does, it produces an overall background. The larger pores are called macroporosity. In castings,

porosity is not usually considered a defect, unless it is extensive enough to cause a structural weakness or allow the

leakage of a fluid intended to be contained by the casting.