T.O. 33B-1-1

2-43

at 40°F (4°C) and about half the viscosity (3 cs) at 120°F (40°C). Other penetrants show a similar range of viscosity

change with temperature. These viscosity changes are significant enough to require the adjustment of dwell times for

temperature extremes.

2.4.5.5.2.5.2

NOTE

The evaporation rate of penetrant is increased at temperatures above 100°F

(37.2°C). Care must be taken to prevent the penetrant from drying.

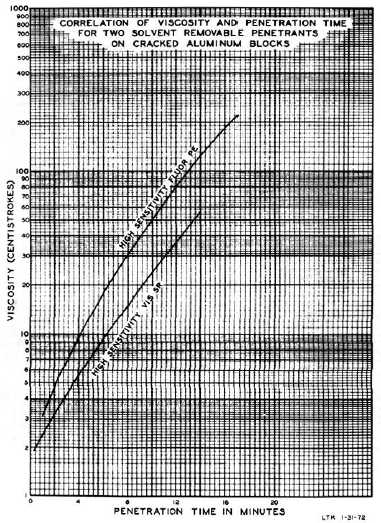

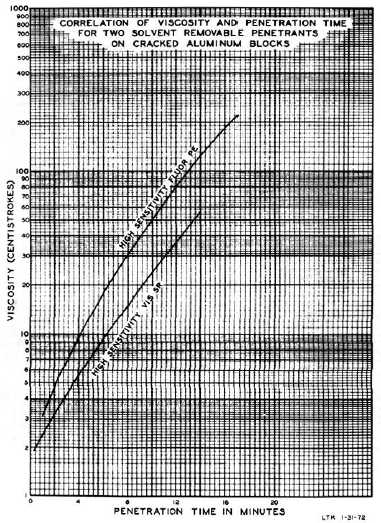

Laboratory experiments show that penetrant dwell time does not have to be changed in the same ratio as the viscosity

changes. Figure 2-13 compares the minimum dwell times for the penetrants previously discussed. The high sensitivity

PE penetrant, with a viscosity of 7 cs at 70°F (21.1°C), required a penetrating time of 3 minutes. At 40°F (4°C), the

viscosity doubled to 14 cs, while the dwell time increased by 1.75 to 5.5 minutes. At 120°F (49C), the viscosity drops

to less than one-half (3 cs) and the dwell time is decreased by two-thirds (1 minute). The thinner visible-dye penetrant,

with a viscosity of 3.6 cs at 70°F (21.1°C), required a penetrant dwell lime of 2.4 minutes. At 120°F (49°C), the

viscosity was reduced by almost one-half (2.0 cs), while the required dwell was reduced to one-fifth of the time (0.5

minutes).

Figure 2-13. Comparison of Dwell Time versus Viscosity for Two Types of Penetrants.