TM 5-3740-214-14

Table 5-1. Direct and General Support Preventive Maintenance Checks and Services

M = Monthly

A/R = As Required

Q = Quarterly

H = Hourly

INTERVAL

ITEM

ITEM TO BE INSPECTED

NO. M A/R

Q

H

PROCEDURE

1

ENGINE ASSEMBLY

500

a. Check crankcase vacuum. Use vacuum gage.

NOTE

The engine must be running to check crankcase vacuum.

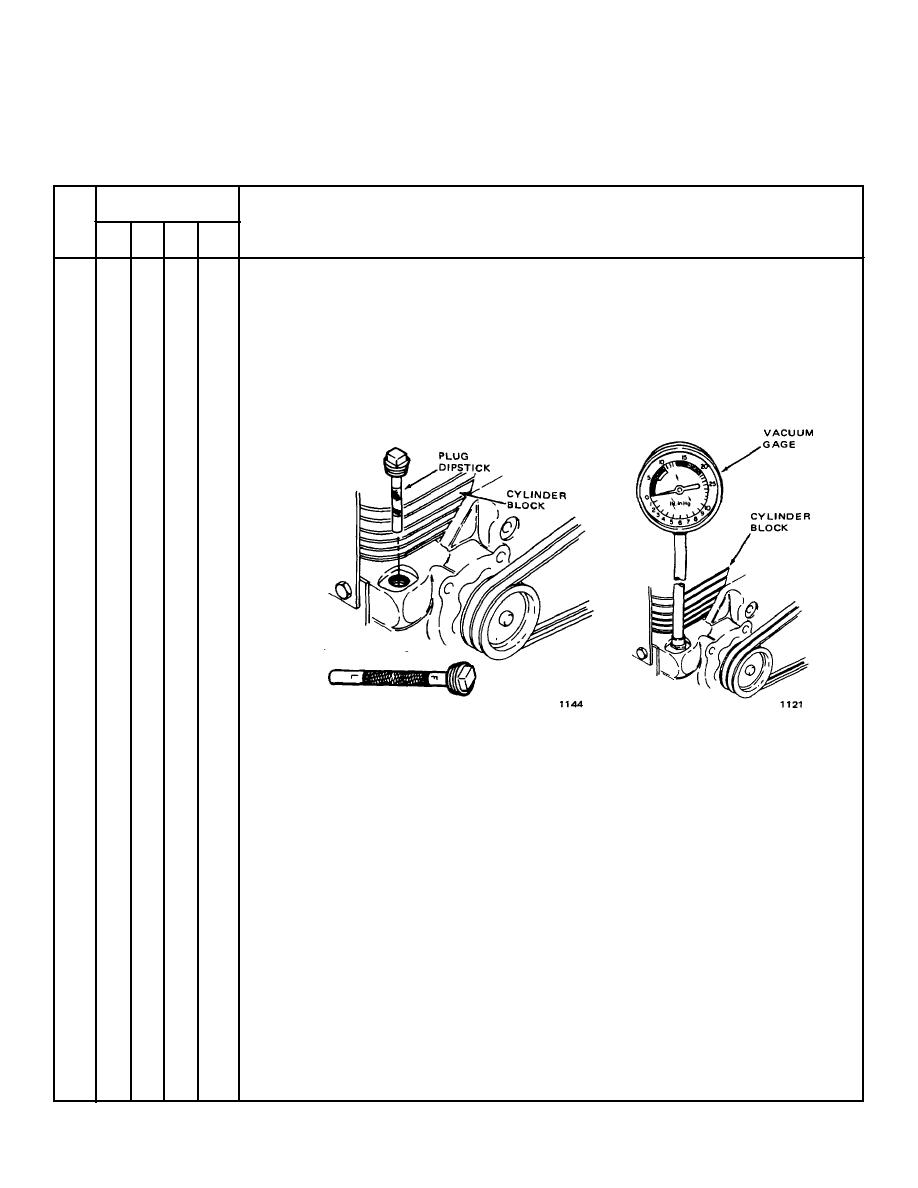

Figure 5-2. Installation of Vacuum Gage

(1)

Remove plug dipstick.

(2)

Insert vacuum gage into dipstick hole. Make sure it seals well.

(3)

Start engine and test vacuum.

(a)

If vacuum is /2 - 1 inch (12.7 - 25.4 mm) of mercury the engine is ok.

(b)

If vacuum is less than 1/2 inch (12.7 mm) of mercury, check crankcase breather.

(c)

If there is a positive pressure in the crankcase, check engine compression.

500

b. Check crankcase breather assembly.

(1)

Remove valve cover and gasket.

5-4