TM 5-3740-214-14

Table 2-1. Operator Preventive Maintenance Check and Services (Continued)

B - Before

D - During

A - After

INTERVAL

FOR READINESS REPORT-

ITEM

ITEM TO BE INSPECTED.

ING, EQUIPMENT IS NOT

NO.

B

D

A

PROCEDURE

READY/AVAILABLE IF:

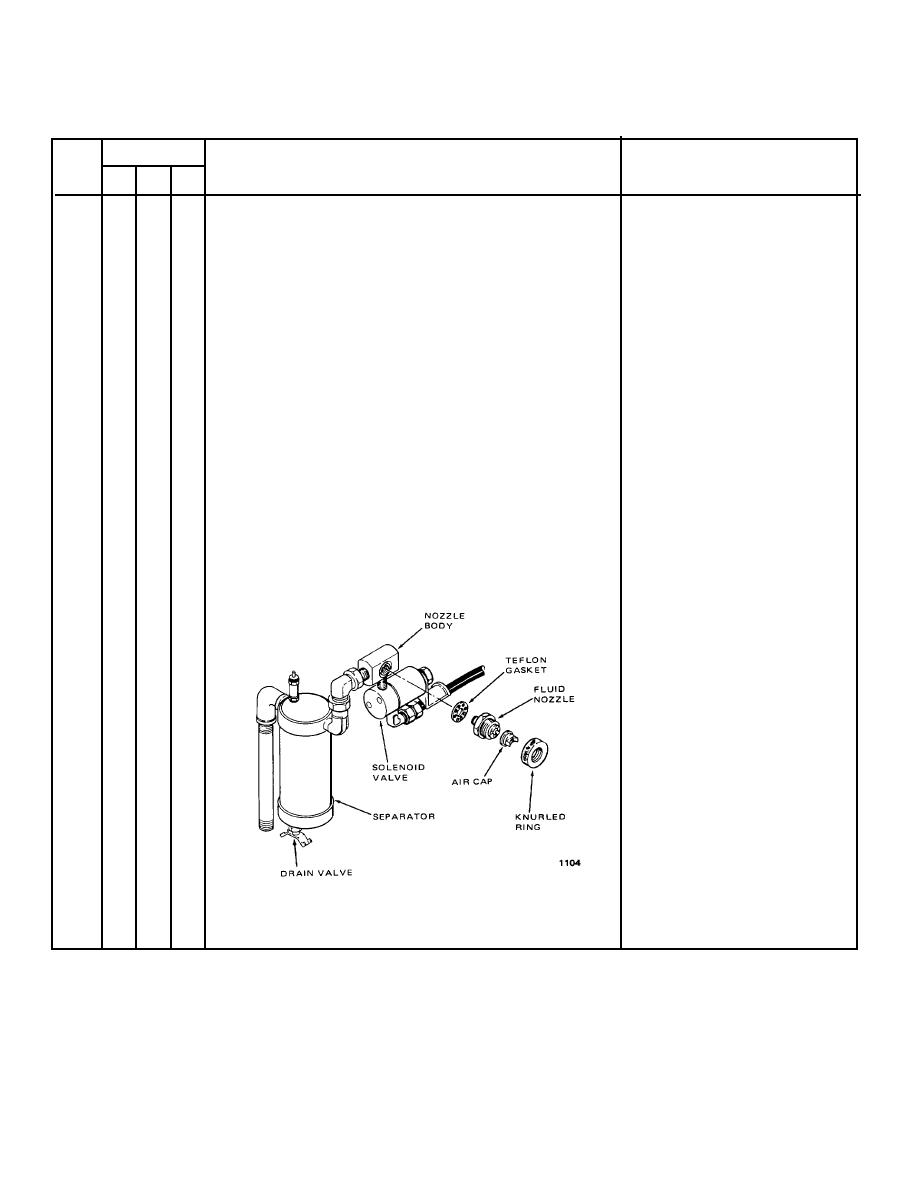

SEPARATOR ASSEMBLY (Continued)

a. Open separator drain valve and drain oil from

There are air leaks around the

separator. Be sure to close valve after oil is drained.

separator or its plumbing

b. Check all separator fittings for air leaks.

9

NOZZLE ASSEMBLY

CAUTION

DO NOT use hard metal objects or probes

to clear out air cap holes. They will damage

the air cap.

DO NOT use too much force to tighten

knurled ring.Tighten knurled ring by hand.

Too much force will damage nozzle assembly.

DO NOT use force to tighten fluid nozzle.

Too much force will damage teflon gasket.

Figure 2-11. Nozzle Assembly

2-9